1.What Is an Industrial Cooking Mixer? Your Ultimate Guide

Industrial cooking mixers serve as the powerhouse behind consistent, large-scale food production. Unlike household units, these robust machines process volumes from 50L to 1000L+ while integrating precision mixing, heating capabilities, and industrial-grade durability for continuous 24/7 operations. They excel at efficiently blending raw ingredients (grains, fruits/vegetables, additives, etc.) to ensure uniform distribution, enhance product texture, and guarantee batch-to-batch consistency. Advanced models further incorporate integrated heating systems and homogenization functions to accommodate diverse production needs—from jams and doughs to sauces and seasonings—all within a single industrial workstation.

2.Why Food Manufacturers Rely on Industrial Mixers

- Efficiency: Mix 500kg batches in minutes

- Integrated Cooking: Mix & heat simultaneously

- Consistency: Uniform texture every batch

- ROI: Reduce labor costs by 60%

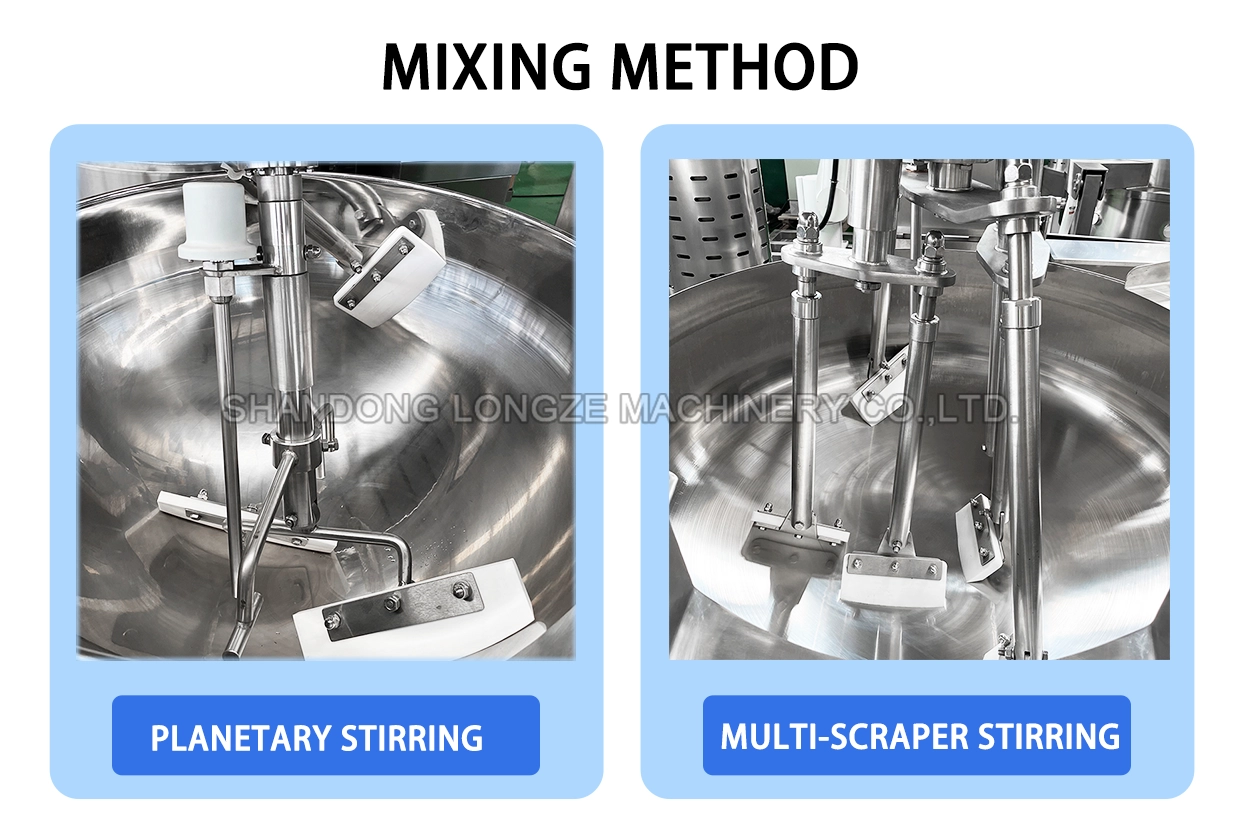

3.Key Types: Planetary vs. Multi-Scraper Mixers

Planetary Cooking Mixer

1). Mixing System

The planetary stirring system features multiple agitator arms mounted on a central shaft. These arms rotate on their own axes while orbiting the main shaft (dual-motion rotation), ensuring 100% scraping coverage of the kettle’s interior. Specially designed blades—including curved, serrated, or hook-shaped variants—penetrate deep into corners and bottom surfaces to eliminate dead zones and efficiently break down bulky ingredients.

2). Kettle Structure

- Constructed with food-grade 304/316L stainless steel

- Hemispherical bottom design for optimal heat distribution

- Available capacities: 100L to 600L

*(Compact 50L models exclusive to gas/induction heating)*

3). Heating Systems

| Method | Key Advantage | Ideal Application |

| Gas Heating | Rapid heat-up (<3 mins) | Bulk meat processing |

| Induction | Precision control (±1°C) | Large-batch sauces |

| Steam | No scorching risk | Protein blends, baby food |

| Thermal Oil | High-temp stability (260°C) | Candy, high-viscosity fats |

Multi-Scraper Cooking Mixer

1). Mixing System

Engineered with PTFE-coated scraper blades (FDA-compliant), these mixers utilize 3-6 independently rotating “claws” that simultaneously:

- Rotate around the central axis

- Maintain constant wall-to-bottom contact

- Gently fold ingredients without crushing

Result: Zero-residue scraping for fragile mixtures like chocolate or fruit compotes.

2). Kettle Structure

- Mirror-polished stainless steel construction

- Flat-arched bottom for even paste distribution

- Industrial-scale capacities: 300L to 1000L+

3). Heating Systems

| Method | Key Advantage | Ideal Application |

| Gas Heating | High thermal power (260°C+) | Searing, frying |

| Induction | Precision control (±1°C) | Sauces, delicate emulsions |

| Steam | Gentle, uniform heating | Jams, dairy products |

| Thermal Oil | Steady high-viscosity processing | Thick pastes, dough |

4.How to choose an industrial mixer

Planetary Mixer Applications

1). Food Processing Plants

Ideal for precision mixing of sauces (tomato/peanut butter), pastes (fillings, ointments), and viscosity-sensitive products. Ensures batch-to-batch consistency in large-scale production.

2). Pharmaceutical Industry

Meets GMP standards for blending medicinal creams, syrups, and topical formulations with ±0.5°C temperature control.

3). High-End Restaurants

Enables Michelin-starred kitchens to craft delicate emulsions, dessert fillings, and signature sauces with zero scraping residue.

4). Retail Bakeries & Kitchens

Compact 50L-200L models fit space-limited operations for daily production of artisanal products.

Multi-Scraper Mixer Applications

1). Households & Small Catering

Rapidly mixes 20-100L batches of dumpling fillings, meatballs, or batters with effortless cleanup.

2). Traditional Food Workshops

Handles heritage recipes (dim sum fillings, spice blends) using time-preset programs.

3). Industrial Food Factories

- 1,000L capacity (≈500kg/batch) for mass production

- IoT-enabled automation: Stores 20+ recipes, monitors viscosity/temperature in real-time

- Ensures flavor standardization for global supply chains (e.g., pizza sauces, curry pastes)

Industrial cooking mixers are the cornerstone of modern food manufacturing, transforming raw ingredients into consistent, high-quality products at scale. Whether you require the precision of a planetary mixer for pharmaceutical-grade emulsions or the massive throughput of a 1,000L multi-scraper unit for global sauce production, selecting the right combination of stirring mechanism, heating system, and capacity is critical.

From 50L compact planetary units for boutique bakeries to IoT-enabled 1000L+ multi-scraper systems for Fortune 500 food brands, our engineering team delivers tailored mixing solutions that boost your productivity by up to 300%. Ready to revolutionize your production line?

Contact us through the contact information or leave a message, we will provide you with free consultation and customized solutions.