The global gourmet popcorn market is exploding — projected to grow from $4.87 billion in 2025 to $9.2 billion by 2033, fueled by rising demand for healthy, innovative snacks and expanded retail distribution 3. For entrepreneurs and established food processors alike, this represents a golden opportunity. But success hinges on one critical factor: selecting the right industrial-scale equipment. This comprehensive guide details the machinery and strategic insights needed to launch or scale a competitive popcorn operation in 2025.

1. Why the Popcorn Business is Booming: Market Shifts Creating Opportunity

Consumer preferences are driving unprecedented diversification:

Flavor innovation: Salty ($1.1B market value), sweet ($1.5B), cheese ($0.9B), and spicy ($0.7B) varieties dominate 2025 preferences, with hybrid flavors gaining traction.

Premium packaging: Stand-up pouches (freshness-focused) and branded buckets (experience-focused) command price premiums, especially for theater and gift markets.

Health-conscious demand: Protein-enriched and plant-based options are disrupting traditional recipes 58.

Distribution channels: Supermarkets lead sales, but online retail is the fastest-growing segment due to convenience and discover ability.

2. Core Equipment: Your Production Powerhouse

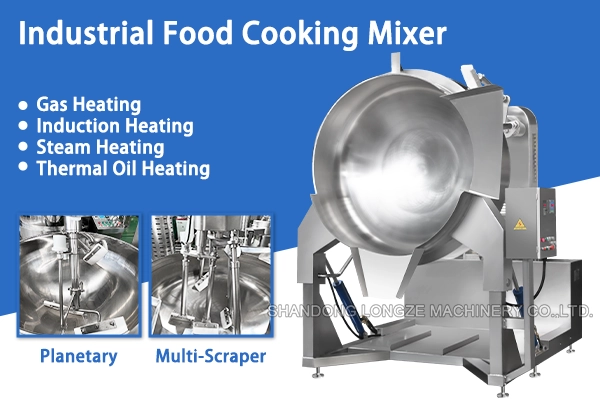

* At the heart of your operation is the industrial popcorn machine. Cutting corners here risks bottlenecks, inconsistent quality, and hidden costs. Today’s leaders prioritize:

Oil-popping technology: Eliminates need for separate coating machines by infusing flavors directly during cooking (e.g., spicy, cheese, or caramel).

Heating flexibility: Choose between gas (lower upfront cost) or electromagnetic (precision temperature control + higher yields + more efficient).

Stainless steel construction: Mandatory for food safety, durability, and compliance with global standards (ISO9001, CE) 24.

* High-Capacity Popcorn Machine Comparison

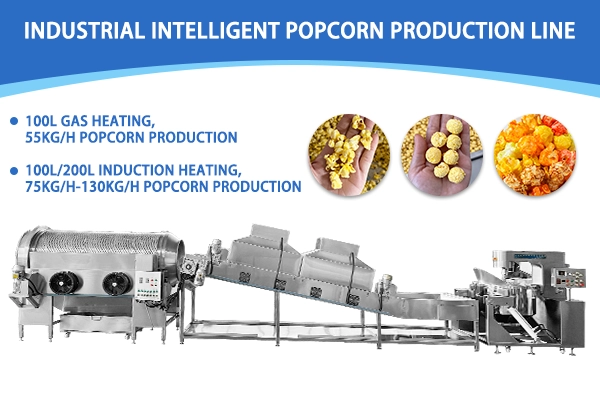

| Model | Heating Method | Capacity(Customizable) | Output/Hour | Best For |

| LZ-RQB-100L | Gas | 100L | 55kg | Startups, low-energy-cost regions |

| LZ-DCB-100L | Electric Induction | 100L | 75kg | High-volume retail, mid-size factories |

| LZ-DCB-200L | Electric Induction | 200L | 130kg | Large processing plants, OEM supply |

| We also have popcorn production line for you to choose. The shortest production line is 7 meters which can accommodate one popcorn machine. 9 meters can accommodate 2 units. 10 meters can accommodate 3 units. 14 meters can accommodate 4-5 units. The popcorn production line consists of four parts: Conveyor, Detaching, Cooling, and Sifting Roller.(After these four steps, the popcorn can be packaged directly) | ||||

*All models feature direct oil-popping technology and SUS 304 stainless steel construction.*

3. Strategic Considerations Beyond Machinery

Power Requirements: Electromagnetic models (LZ-DCB-100L/200L) need 3-phase power but reduce thermal loss vs. gas.

Space Planning: The area occupied by a popcorn machine is about 3.5㎡-6㎡. The production line covers an area of about 12.5㎡-26㎡.

Compliance: CE certification is non-negotiable for export markets 27.

Your success in the popcorn gold rush starts with precision-engineered equipment. With the LONGZE MACHINERY popcorn machine series’ oil-popping technology, you eliminate costly coating machines and unlock unlimited flavors in one step. Request a custom production quote or explore our factory test drive program.