Seeking reliable high-yield popcorn machines for commercial production? As global demand for ready-to-eat flavored popcorn surges, investing in industrial-grade equipment becomes critical. Discover why Shandong Longze Machinery’s oil-popping technology outperforms traditional methods, eliminating the need for separate coating machines while delivering 55-130kg/hour production capacity…

Industrial Automatic Gas Heating Popcorn Machine (55kg/h)

1. Revolutionize Production with Oil-Popping Technology

Flavor Fusion Innovation

Directly infuse flavors during popping—no post-process coating required. Produce caramel, cheese, chili, or custom flavors in a single step, reducing equipment costs and floor space.

Energy-Efficient Heating Options

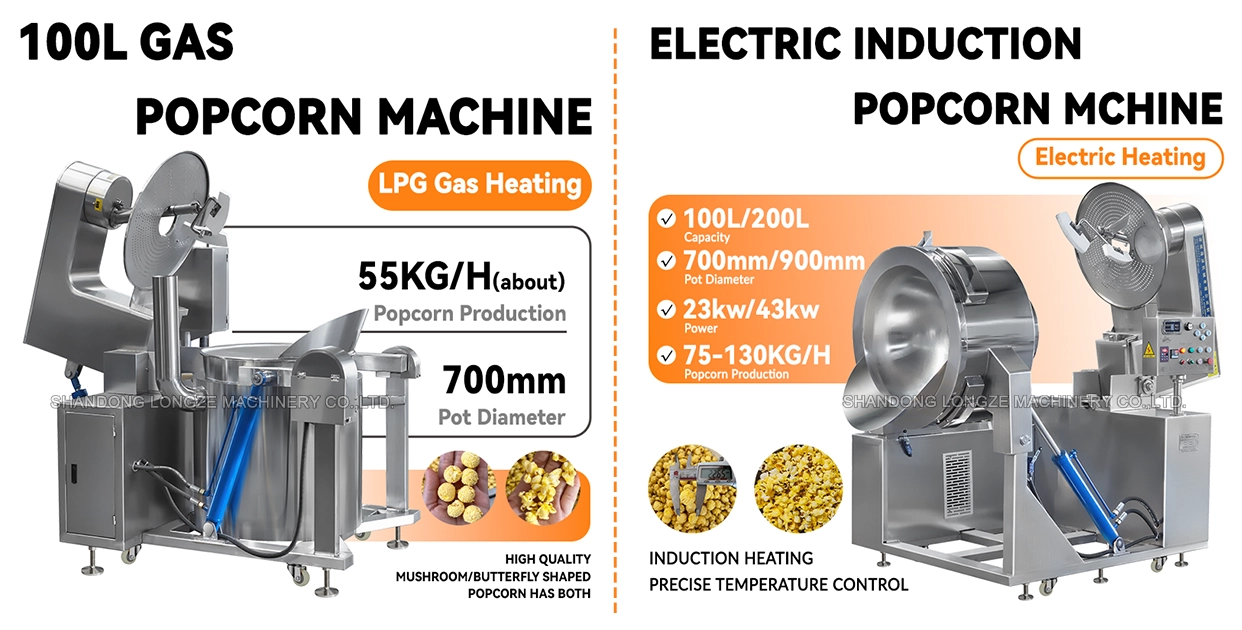

* 100L Gas-Powered System

Uses LPG as fuel, Ideal for regions with unstable electricity: 55kg/h output, low operational costs

* Electromagnetic Series (100L/200L)

The electric induction uses induction heating, which is the most advanced heating method. It can start and stop heating immediately. It heats the inner pot directly, 8 gears to adjust heating strength, it has the advantages of fast heating and high thermal efficiency, more intelligent and stable than gas heating.75kg/h (100L) to 130kg/h (200L) output.

2. Technical Specifications

| Model | Heating Mode | Output | Output | Dimensions (mm) |

| Gas Heating | LPG | 55kg/h | Button Control | 1207×1500×1500 |

| Electric Induction | Electric Induction 20kW | 75kg/h | Button/Intelligent | 1565×1373×1606 |

| Intelligent Electric | Electric Induction 40kW | 130kg/h | Button/Intelligent/Automated Feeding | 1541×1851×1675 |

3.Product Advantages

– Every component crafted in SUS304 stainless steel – including bolts, base plates, and internal mechanisms – delivering corrosion resistance for salt/sugar-heavy environments and meeting FDA food contact standards.(Customizable 316 pot liner)

– LPG gas heating/Electromagnetic induction rapid heating, with 8 heating levels, temperature control

– Automatic operation with control panel/Fully automatic with German Siemens PLC system or control panel

– Planetary mixing to avoid burnt or sticky together

– Famous brand gear motor reducer, silent mode and no need maintenance

– Directly produce flavored/seasoning/savory popcorns, no need other coating machine

– Durable quality to enable continuous operation 24/7