Commercial jam producers face oxidation challenges causing color fading and nutrient loss. Our vacuum horizontal mixers solve this with…

1.Technical Parameters

| Feature | Specification |

| Capacity | 300L / 500L / 800L |

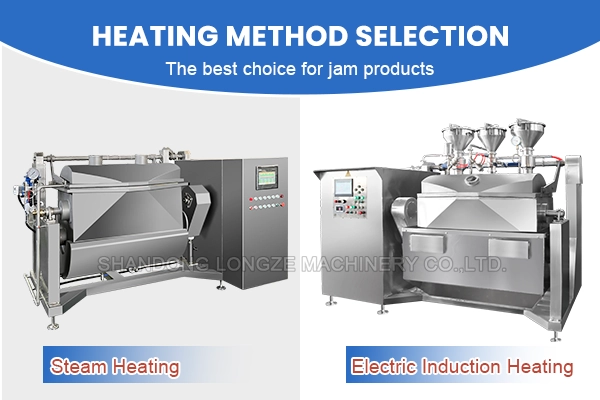

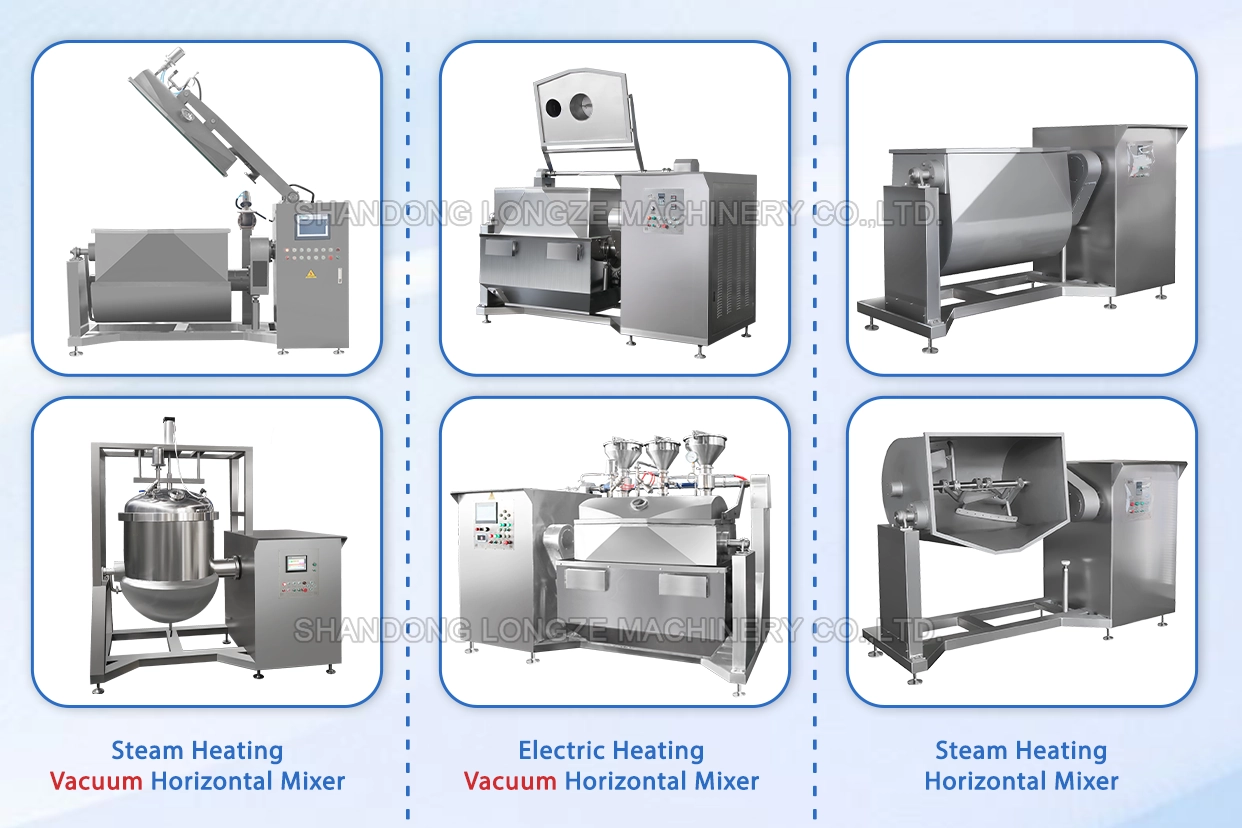

| Heating Method | Steam / Electromagnetic Induction |

| Mixing Technology | Bidirectional 360° Agitation |

| Material Handling | Chunks, Granules, Pastes |

| Vacuum Degree | -0.09 to -0.05 MPa |

2.Vacuum Horizontal Mixer: Key Benefits for Superior Food Production

In the competitive food processing industry, the vacuum horizontal mixer is a revolutionary solution that enhances product quality, operational efficiency, and compliance with food safety standards. Here’s why this advanced mixer is a must-have for food manufacturers:

1). Oxidation Prevention – Maintains Freshness & Color

Exposure to air degrades food quality, leading to discoloration and flavor loss—especially in delicate products like pineapple/strawberry jam, apricot preserves, and nut butters. The sealed vacuum environment eliminates oxygen, preventing oxidation and preserving:

* Vibrant natural colors (e.g., pineapple/strawberry jam stays bright red)

* Fresh taste and aroma (no off-flavors from oxidation)

* Longer shelf life (reduced spoilage risk)

2). Enhanced Nutrient Retention – Healthier, Higher-Quality Products

Traditional mixers expose ingredients to oxygen and heat, degrading heat-sensitive nutrients like vitamin C and antioxidants. The vacuum horizontal mixer reduces nutrient loss by 30-45%, ensuring:

* Higher vitamin and mineral content in jams, sauces, and functional foods

* Better alignment with consumer demand for nutritious products

* Improved product labeling claims (e.g., “high in vitamin C”)

3). Superior Mixing Uniformity – Perfect Texture Every Time

Inconsistent blending leads to clumps, uneven distribution, and product waste. This mixer features dual-direction rotating blades for 98%+ uniformity, ensuring:

* Smooth, lump-free textures in high-viscosity products (fruit purees, dairy blends)

* Consistent batch quality (reducing waste and customer complaints)

* Efficient processing (faster mixing cycles, higher productivity)

4). Smart PLC & IoT Control – Smarter, Faster Production

The advanced PLC (Programmable Logic Controller) and IoT integration optimize operations with:

* Remote monitoring & troubleshooting – Real-time tracking of speed, pressure, and runtime; engineers can diagnose issues remotely, reducing downtime.

* 20+ preset programs – Quick switching between recipes (e.g., low-sugar jam to high-fiber spreads) for flexible, high-speed production.

5). Precision Temperature Control – Prevents Overheating

Fluctuating temperatures can ruin food texture and nutrients. The mixer’s wireless temperature control ensures:

* Exact heating (±1℃ accuracy) for melting, pasteurization, or mixing

* Auto shut-off at preset temps (prevents overheating, preserves quality)

* Less manual oversight (saves labor costs)

6). Hygienic, Easy-to-Clean Design – Meets Food Safety Standards

Strict hygiene is critical in food processing. This mixer is designed for easy cleaning and compliance:

* 304/316L stainless steel construction (rust-proof, anti-bacterial)

* No dead zones – Smooth, rounded surfaces reduce cleaning time by 80%

* Meets global food safety regulations (FDA, EU, HACCP compliant)

Investing in a vacuum horizontal mixer means higher-quality products, improved efficiency, and greater profitability—making it an essential tool for modern food production.

3.FAQs About Vacuum Horizontal Mixers – Buyer’s Guide

A1. Can the mixer handle sticky materials like caramel or cheese?

Q1: Yes! Our mixer is designed for high-viscosity ingredients, featuring:

* Food-grade stainless steel & Teflon scrapers (prevents sticking)

* Custom-engineered accessories (optimal compatibility & performance)

* Easy-to-clean design (no residue buildup)

A2. How can I test the mixer’s performance before purchasing?

Q2: We offer FREE sample testing using your actual materials—contact us to arrange a trial!

A3. Why choose LONGZE Machinery?

Q3: 14+ years of expertise in food processing equipment

* Specialized in bulk production (high-efficiency solutions)

* Professional R&D, production & after-sales teams

* Fast global support (24/7 remote troubleshooting)

A4. What after-sales services do you provide?

Q4: 14 year full machine warranty core component warranty

* Emergency spare parts included with delivery

* Lifetime maintenance support + video-guided repairs

A5. What’s the delivery time?

Q5: 15–30 days after deposit (varies by order size & customization). Need it faster? Ask about expedited options!

A6. Where are your products sold, and what’s your market advantage?

Q6: Exported to 45+ countries (Europe, Americas, Asia, Africa) with 3-year sales growth thanks to:

* Premium build quality (strict ISO-compliant manufacturing)

* Innovative R&D (custom solutions for unique needs)

* Reliable pre-sale & after-sale service