Key Features & Benefits: Engineered for Excellence

1. Versatile Heating System for Precise Thermal Control

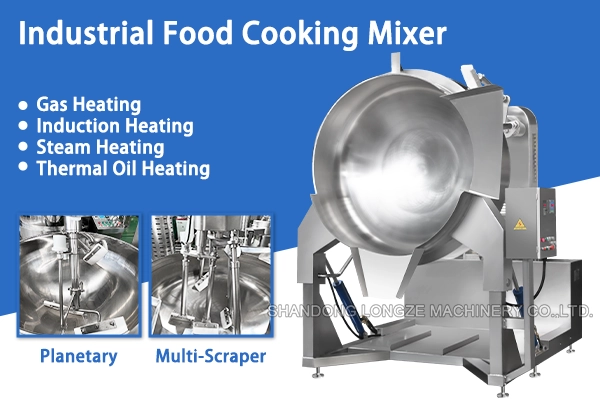

Choose the optimal heating method for your energy availability and product requirements:

* Gas Heating: Offers rapid heating and traditional control, ideal for high-temperature applications.

* Electromagnetic (Induction) Heating: Provides exceptional energy efficiency, pinpoint temperature accuracy, and a cooler, safer workspace.

* Steam Heating (Jacketed): Ensures gentle, uniform heating, perfect for temperature-sensitive products like dairy-based sauces or delicate emulsions.

* Thermal Oil Heating: Delivers stable, high-temperature heating (beyond steam’s limit) for processes requiring temperatures above 150°C, such as confectionery or certain frying preparations.

2. Advanced Stirring Technologies for Perfect Consistency

Select the stirring action that matches your product viscosity and mixing goals:

* Planetary Stirring System: The agitator rotates on its own axis while simultaneously orbiting the mixing bowl. This creates a complex, thorough motion that eliminates dead zones, ensuring perfect homogeneity for medium to high-viscosity products like thick pastes, batters, and meat mixtures. Capacity range: 100L to 600L (50L available for gas and induction models).

* Multi-Scraper Stirring System: Equipped with multiple blades that continuously scrape the inner wall of the kettle. This prevents burning and sticking, ensuring efficient heat transfer and a consistent mix for large-batch, often sticky products like jams, caramel, or savory sauces. Capacity range: 300L to 1000L.

3.Intelligent Control & Safety

* A user-friendly PLC touchscreen interface allows for precise programming of time, temperature, speed, and sequences. Operators can save and recall recipes for flawless, repeatable batches. Integrated safety features, including overload protection, emergency stop, and fail-safe temperature controls, ensure reliable and secure operation.

Technical Specifications at a Glance

| Feature | Specification & Options |

| Product Name | Industrial Multifunctional Cooking Mixer |

| Construction | 304/316 Food-Grade Stainless Steel |

| Heating Methods | Gas, Electric Induction, Steam, Thermal Oil |

| Stirring Types | Planetary Stirring, Multi-Scraper Stirring |

| Capacity Range | Planetary: 100L-600L (50L option for Gas/Induction) Multi-Scraper: 300L-1000L |

| Application | Sauces, Dressings, Condiments, Jams, Fillings, Soups, etc. |

| Control System | Programmable PLC with Touchscreen & Recipe Memory |

Ideal Applications Across the Food Industry

This machine is a cornerstone for diverse food sectors:

Sauce & Condiment Producers: For ketchup, mayonnaise, hot sauce, pasta sauce, and salad dressings.

Dairy & Non-Dairy Plants: For cheese sauces, pudding, yogurt mixes, and plant-based spreads.

Bakery & Confectionery: For fruit fillings, custards, chocolate, caramel.

Ready-Meal & Soup Manufacturers: For batch cooking of soups, stews, and curry bases.

Meat & Poultry Processors: For marinades, seasoning mixes, and ready-to-cook preparations.