Traditional open-air mixers cause oxidation loss in fruit jams, resulting in flavor degradation and color fading. Our vacuum technology solves this by mixing under -0.09MPa to -0.05MPa pressure environment, preserving natural anthocyanins and vitamin content.

1.Why Vacuum Mixing Matters

Flavor Lock Technology: Removes air pockets during mixing, preventing oxidative damage to delicate fruit compounds. Ideal for jams, fruit preserves, tomato paste requiring vibrant appearance.

Homogeneity Achieved: Counter-rotating blades with alternating bidirectional rotation create 360° mixing motion, ensuring thorough ingredient integration without stratification. Processes chunky, granular, and paste-form materials with consistent results.

Hygienic & Easy-Clean Design: Constructed with full stainless steel (304/316L), featuring dead-zone-free bottom-and-wall-scraping mixing design. Corrosion-resistant and easy-clean, complying with food sanitation and safety standards.

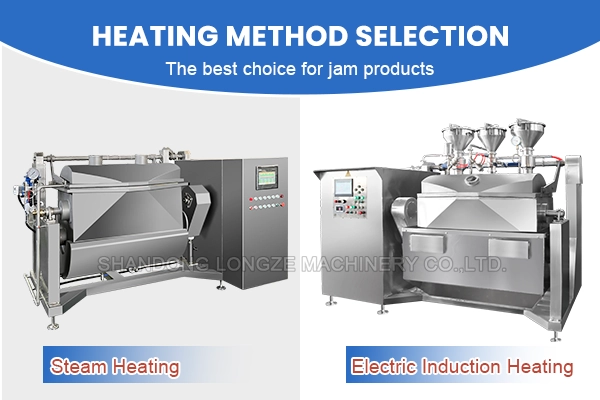

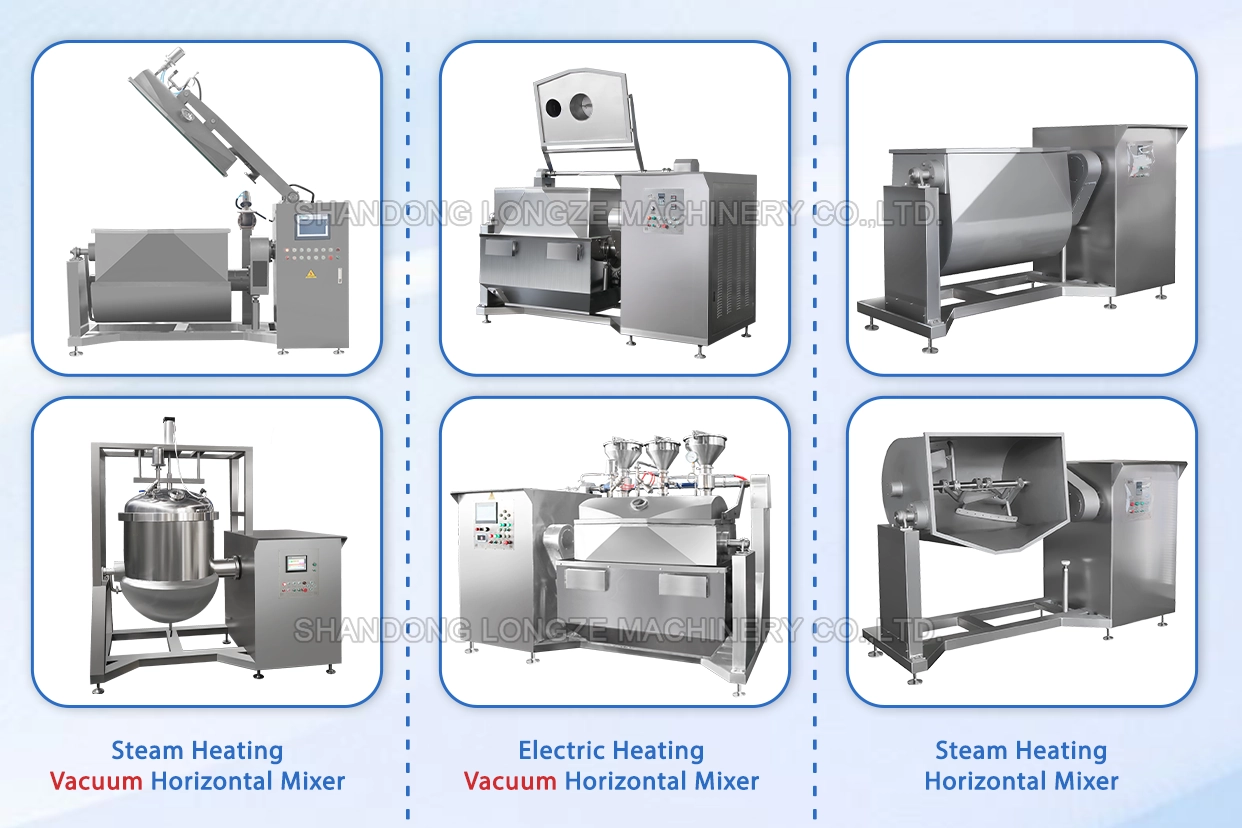

2.Heating System Comparison

| Feature | Steam Heating Mixer | Induction Heating Mixer |

| Heating Rate | 1.5°C/min | 3.2°C/min (380V/50Hz) |

| Temp Control | ±2°C | ±0.5°C |

| Best For | High-viscosity recipes | Precision-sensitive emulsions |

| Pressure Range | (-0.09)to(-0.05)MPa | |

| Mixing Capacity | 300L/500L/800L Customizable | |

| Temperature Control | 40℃-70℃ | |

| Motor power | 3-7.5kw | |

| Stirring Speed | 0-80r/min | |

3.Applications: Solve Your Specific Production Challenges

Candied & Dried Fruits: Even sugar/seasoning coating on plums, apricots, pineapple slices without crushing

Concentrated Products: Homogeneous blending of fruit purees, nut butters, baby food with zero lumps

Pickles & Fermented Foods: Gentle mixing of kimchi, sauerkraut, spicy turnips while retaining crispiness

Powder & Granule Mixtures: Dust-free operation for spice blends, instant soup bases, nutritional powders

4.Why Choose Our Machine?

* Tailor-made for overseas customers: Designed to withstand high humidity and local power grid environment.

* 24/7 support: 24-hour online service, remote service guidance, lifelong remote maintenance

* We have 14+ years of manufacturing experience.We have professional technical department, which have serviced more than 45 countries and regions,can provide fastest customization service.

* Each machine will be strictly tested before leaving the factory, and customers can conduct on-site or online acceptance according to their needs.

* Complete machine warranty: 1 year; critical components warranty: 5 years

* Standard replacement parts are provided to customers upon factory shipment