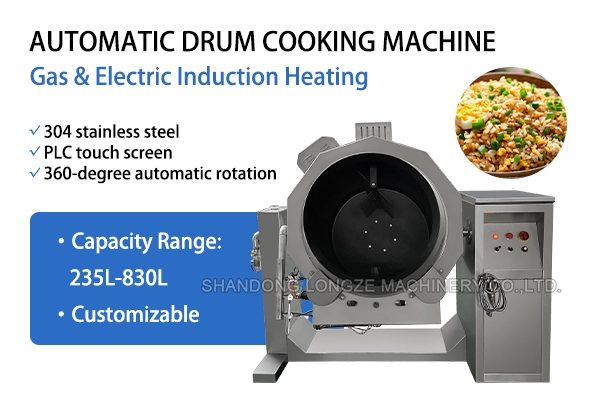

Our Industrial Intelligent Automatic Drum Cooking Machine is a professional-grade cooking equipment engineered for large-scale food processing. It integrates advanced automation technology with a durable drum structure, enabling automatic stirring, temperature control, and cooking process management—eliminating the need for heavy manual labor and reducing human error. Available in two heating modes (gas and electromagnetic) to adapt to different on-site energy conditions, and with a capacity ranging from 235L to 830L, it can handle everything from small-batch specialty food production to mass-produced staples (such as sauces, fillings, stir-fried vegetables, meat products, and convenience foods).

What sets this machine apart is its full customization capability. We tailor every detail to your specific needs—whether adjusting the drum size, modifying the heating power, adding special stirring paddles for viscous materials, or integrating with your existing production line. It complies with international food safety standards (such as CCC, CE) and is suitable for food manufacturers across Asia, Europe, North America, and other global markets.

| Heating Method | Model | Dimensions(mm) | Motor Power(Kw) | Heating Method | Diameter(mm) | Volume(L) | Output(Kg) For reference only |

| Gas/Induction | LZ-GT-235 | 1480*1160*1600 | 0.75 | LPG/NG/Electric | 600 | 235 | 25kg |

| LZ-GT-350 | 1520*1160*1630 | 0.75 | LPG/NG/Electric | 700 | 350 | 25-50kg | |

| LZ-GT-500 | 1650*1260*1720 | 1.1 | LPG/NG/Electric | 800 | 500 | 40-80kg | |

| LZ-GT-650 | 1750*1280*1800 | 1.1 | LPG/NG/Electric | 900 | 650 | 60-100kg | |

| LZ-GT-800 | 1880*1530*1800 | 1.1 | LPG/NG/Electric | 1000 | 800 | 80-150kg | |

| LZ-GT-830 | 1880*1430*1900 | 1.1 | LPG/NG/Electric | 1100 | 830 | 180kg |

Why Our Intelligent Drum Cooking Machine Stands Out

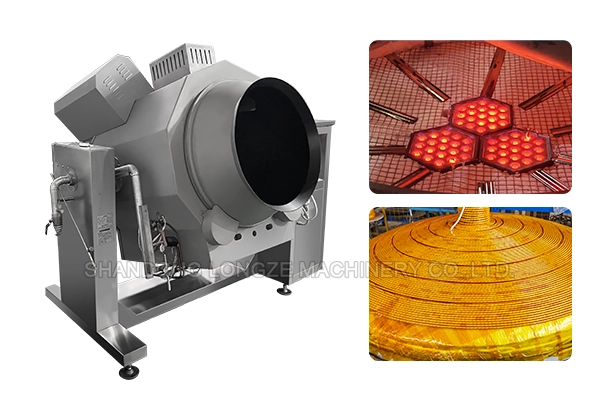

Superior Heating Flexibility: Choose between efficient Gas heating for powerful thermal input or advanced Electromagnetic Induction heating for pinpoint temperature control and exceptional energy efficiency. Cater to your specific utility infrastructure and product requirements.

Fully Customizable Capacity: Our machines are tailored to your needs, available in a wide range of sizes from 235L to 830L, perfectly scaling from pilot plants to high-volume industrial production.

Intelligent Automation & Control: Equipped with a user-friendly PLC touch screen interface. Precisely program and store recipes for temperature, rotation speed, and cooking time, ensuring batch-to-batch consistency and reducing operator error.

Unmatched Consistency & Quality: The rotating drum design ensures every single piece is heated evenly from all sides, eliminating hot spots and guaranteeing a uniformly cooked product with perfect color, texture, and taste every time.

Enhanced Productivity: Automate one of the most labor-intensive steps in your kitchen. Handle large volumes effortlessly, significantly increasing your hourly output and reducing reliance on skilled labor.

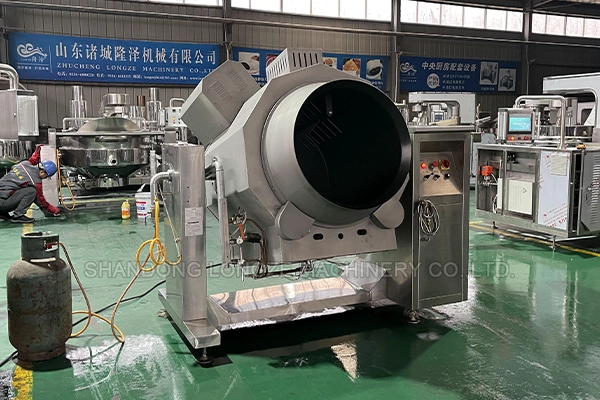

Durable Industrial Construction: Built to last with high-quality, food-grade stainless steel (e.g., SS304/316) for all contact parts, ensuring compliance with international hygiene standards and withstands the rigors of 24/7 operation.

Ease of Cleaning & Maintenance: Designed with hygiene in mind. Features like a tilting drum for easy discharge and access, along with smooth surfaces, simplify the cleaning process and reduce downtime.

Application Fields

Our Industrial Intelligent Automatic Drum Cooking Machine is widely used in:

Food processing plants: Producing sauces (tomato sauce, soy sauce), fillings (mooncake, dumpling), meat products (braised pork, sausage), and convenience foods (instant noodles, frozen stir-fries).

Central kitchens: Catering to schools, hospitals, airports, and chain restaurants (mass-producing daily meals with consistent quality).

Specialty food factories: Making ethnic foods (curries, kimchi), baby food (purees), and pet food (wet food).

Catering enterprises: Handling large-scale events (weddings, conferences) with high-volume cooking needs.

How It Works

Feeding: Add ingredients (raw materials, seasonings) into the drum via the feeding port (manual or automatic conveyor).

Setting Parameters: Use the touchscreen to set cooking temperature, stirring speed, and time (save recipes for future use).

Heating & Stirring: The machine starts heating (gas or electromagnetic) and stirring— the drum rotates slowly, and paddles ensure even mixing.

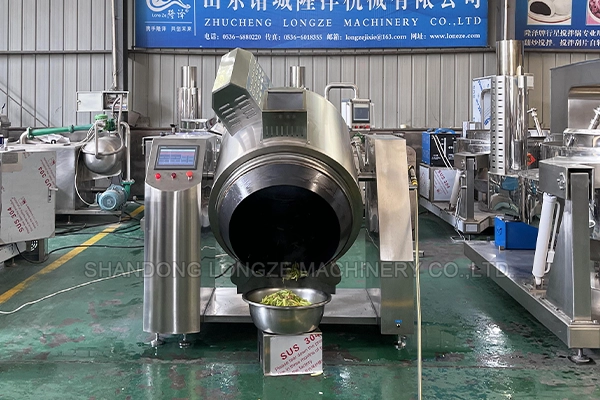

Cooking Completion: When done, the machine alarms, and the drum can be tilted (manual or automatic) to discharge the finished product.

Cleaning: Rinse the stainless steel drum and paddles with water—no dead corners for easy cleaning.

Investing in an Industrial Intelligent Automatic Drum Cooking Machine is an investment in the future of your food production business. It directly addresses the core challenges of scalability, consistency, energy costs, and labor shortages. By offering customizable sizes and the critical choice between Gas and Induction heating, we provide a solution tailored to your specific operational needs.

Contact us today to discuss your customization needs and get a free quote!