Shandong Longze Machinery Co., Ltd specializes in manufacturing industrial-grade professional pressure cookers (100L–800L) with four heating modes (gas, electromagnetic, steam, and thermal oil).our machines excel in high-volume food processing, sterilization, and cooking for industries like canned food production, ready-to-eat meals, pharmaceuticals, and chemical processing. With 14+ years of expertise, we’ve served 300+ clients across 45+ countries, delivering robust solutions tailored to global standards.

We have developed a pressure cooker based on the common pressure cooker, which is suitable for boiling bones and meat into soup, filtering materials and automatically producing soup. This is our company’s patent.

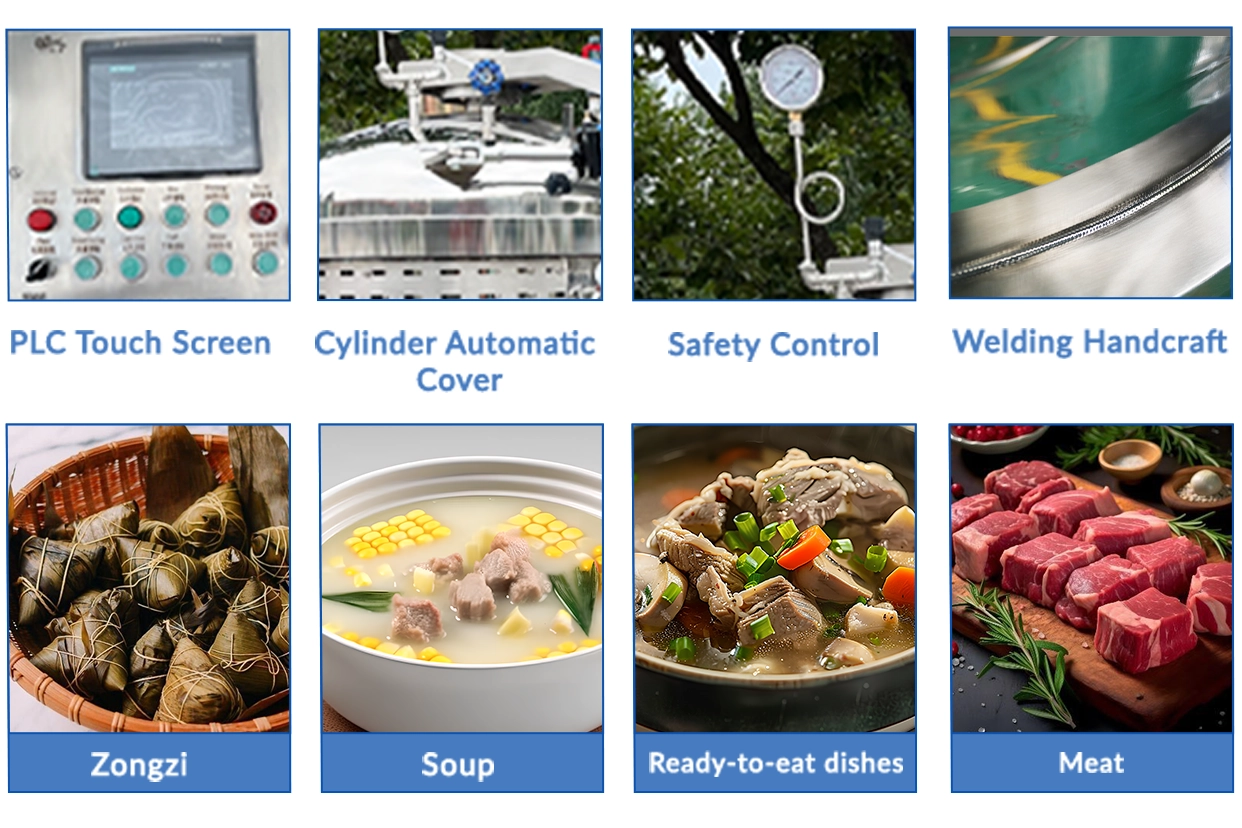

1.Key Features & Benefits

| Feature | Technical Advantage | Business Value |

| Multi-Fuel Heating | Gas (far infra-red burner), Electromagnetic (±1°C precision), Steam (0–1MPa), Thermal Oil (280°C+) | Adapt to any energy infrastructure; reduce fuel conversion costs by 25% |

| Smart Safety System | Triple safety locks, 10-second emergency pressure release, 24/7 corrosion resistance | Meets FDA/HACCP requirements; zero safety incidents reported since 2018 |

| Scalable Capacity | Regular capacity 200L-800L(Other capacities can be customized) | Optimize ROI with modular expansion; shorten production cycles by 30% |

| Energy Efficiency | Electromagnetic models save 40% energy; insulated design reduces heat loss by 25% | Cut annual energy costs by $7,000+ (based on 5-ton daily processing) |

2.Technical Specifications

| Parameter | Details |

| Capacity | 200L,300L,400L,500L,600L,700L,800L(customizable) |

| Heating Methods | Gas/Electromagnetic/Steam/Thermal Oil |

| Material | 304/316 Stainless Steel |

| Pressure Range | 0.3MPa (customizable) |

| Power Supply | 220V/380V/50Hz (customizable for regions) |

| Operation Method | *Flange:Ring Bolt/Mechanical*Rise:Lifting/Side Discharge*Discharge:Manual/Automatic |

| Control Method | Button/PLC Touch Screen/Remote Control/AIO Control |

| Optional Configuration | Temperature Control/Electric Crane/Basket/High Pressure Water Tap |

3.Application Scenarios & Food Processing Solutions

Our industrial-grade pressure cookers are engineered for diverse commercial environments and food production demands:

*Food Processing Plants

Meat & Poultry Processing:Batch steam cooking of beef, pork or chicken, etc. (50–500kg)

Seafood Factories:Cook crab, shrimp, and shellfish uniformly while preserving texture.

Ready-to-Eat Meal Production:Batch-cook soups, stews, and sauces (200–800L batches) with ±1°C precision.

Vegetable & Legume Processing:Soften beans, lentils, and tough root vegetables 3x faster than traditional boiling.

* Hospitality & Large-Scale Catering

Hotel & Restaurant Chains:Prepare signature broths (e.g., ramen, pho) in 800L batches with gas/induction heating.

Maintain consistent flavor profiles across locations.

School/University Cafeterias:Safely cook 300–500 student meals per cycle.Meet NSF sanitation standards for institutional kitchens.

4.Why Choose Us?

*Proven Expertise: 14+ years in industrial autoclave R&D; 45+ countries served.

*Full Customization: Tailor voltage, language interfaces, and discharge methods (lifting/side/manual).

*End-to-End Support: 48-hour global response; Remote service guidance and remote lifetime maintenance.

*Cost Efficiency: Factory-direct pricing with 5% bulk-order discounts.