Popping Mixing Coating 3 In 1 Machine | Industrial Automatic 100L 55kg/h Gas Heating Popcorn Machine

Our industrial full automatic popcorn machines and production lines are tailored for large-scale operations, combining cutting-edge technology with robust engineering. Here is what sets our systems apart:

1. Key Features

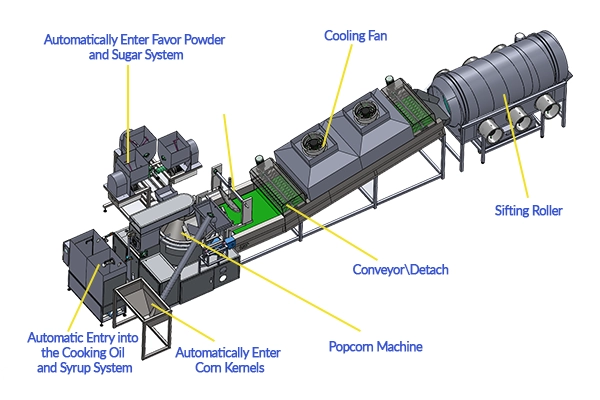

*Oil-Popping Technology: Directly produces flavored popcorn without additional coating machines.

*Modular Design: Integrate with conveyors, detaching devices,cooling fans and sifting rollers for end-to-end automation.

*Material Quality: All stainless steel 304 construction (frame, base plates), ensuring durability and hygiene.

*Intelligent: Equipped with automatic weighing system, automatic loading and unloading. Truly unattended.

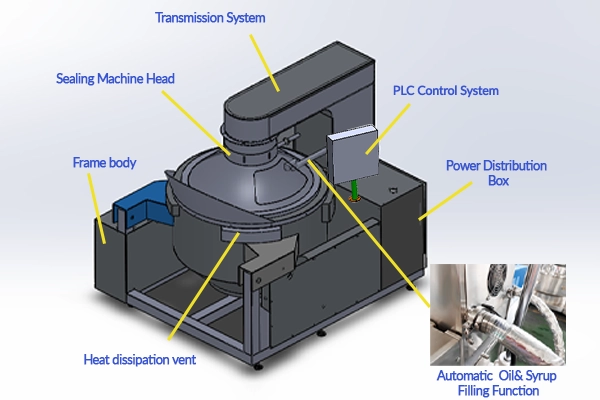

*Standardized production: Equipped with PLC system, which can store 20+ sets of data processes to ensure product consistency.

2.Technical Specifications

| Model | Heating Mode | Output | Output | Dimensions (mm) |

| Gas Heating | LPG | 55kg/h | Button Control | 1207×1500×1500 |

| Electric Induction | Electric Induction 20kW | 75kg/h | Button/Intelligent | 1565×1373×1606 |

| Intelligent Electric | Electric Induction 40kW | 130kg/h | Button/Intelligent/Automated Feeding | 1541×1851×1675 |

Full Automatic Popcorn Production Line Configurations:

Line Length: 7m, 9m, 10m, 14m (customizable).

Machine Sets: 1–5 sets, depending on throughput requirements.

3.Why Choose Us?

*14+ Years of Expertise: Specialized in food processing machinery for bulk production.

*End-to-End Quality Control: Every machine undergoes rigorous testing before shipment.

*Fast Delivery: 15–30 days lead time after deposit confirmation.

*Accessories Production: We have our own parts processing workshop, which has a number of high-precision fiber laser cutting machines, engraving machines, large CNC machine tools, and wire cutting and other high-standard processing equipment. This ensures high coordination between parts and effectively improves the compatibility of the machine. Available spare parts whenever needed.

*Support customized machines: Provide 1v1 customized solutions according to customer products and processes.

*Free on-site trial: You can choose remote online trial or on-site trial.

4.FAQ

Q1: What makes your popcorn machines suitable for large factories?

A1: Our systems offer scalable output, full automation。

Q2: Can you customize production lines?

A2: Yes! We can customize the line length, heating mode (gas/electricity) and flavoring module according to your production needs and factory size.

Q3: How do you ensure after-sales support?

A3: We provide remote diagnostics, spare parts supply, and lifetime free remote maintenance.