Why Choose Our Industrial Popcorn Machines?

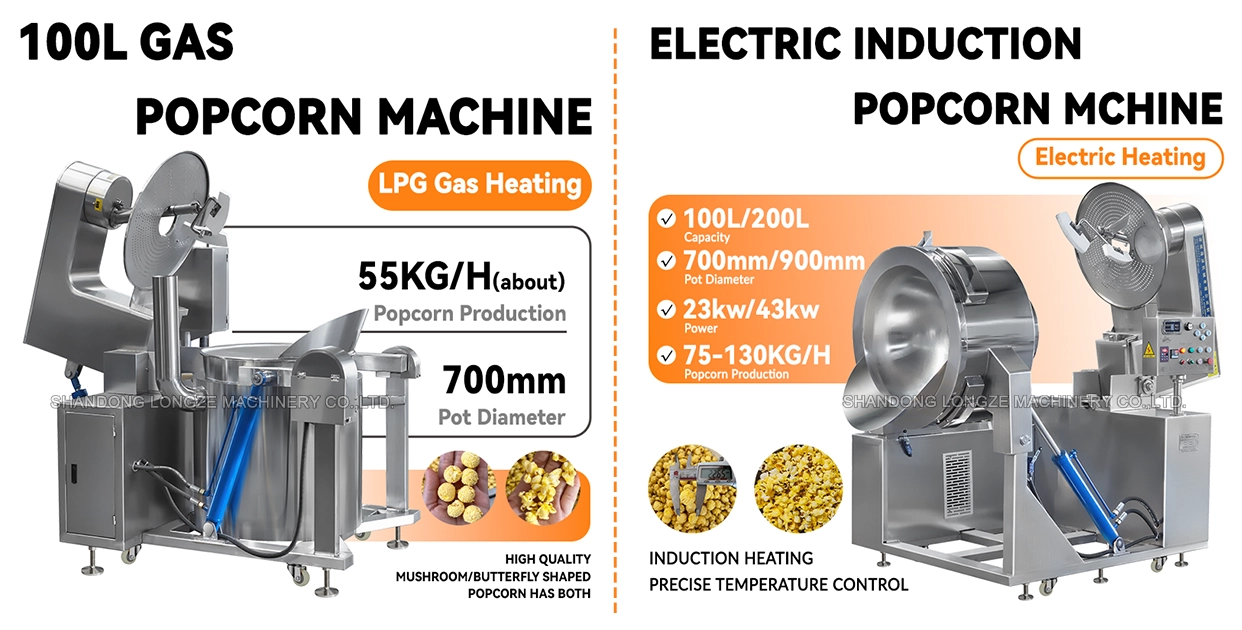

1.Dual Heating Options

100L Gas Heating Model: Achieve up to 55kg/hour production with precise temperature control for consistent popping.

100L & 200L Electric Heating Models: Leverage electromagnetic technology for higher efficiency—75kg/hour (100L) and 130kg/hour (200L)—with reduced energy consumption.

| Model | Heating Mode | Diameter | Motor Power | Stirring Speed | Discharge Type | Control Mode | Production efficiency | Overall dimensions | Advantages |

| Gas | LPG | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button | 55kg/h(5 minutes per batch) | 1207*1500*1500 | Cost-effective for regions with low LPG prices; suitable for medium-volume production. |

| Electric Induction | Electric Induction 20kw | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence | 75kg/h(3.5 minutes per batch) | 1565*1373*1606 | no open flames/exhaust; ideal for eco-conscious facilities. |

| Intelligence Electric Induction | Electric Induction 40kw | 900mm | 2.2kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence/Automatic Feeding | 130kg/h(5.5 minutes per batch) | 1541*1851*1675 | Highest throughput in its class; perfect for large-scale industrial production. |

2.Oil-Based Popping Technology

Our machines use oil-popping methods to directly infuse flavors during the popping process, eliminating the need for additional coating equipment. This ensures rich, even seasoning for caramel, cheese, or any custom flavor profile.

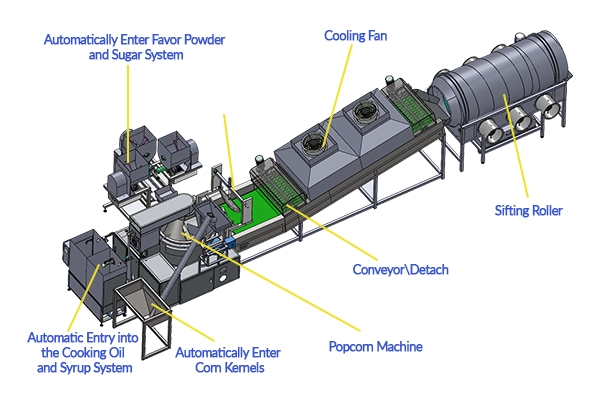

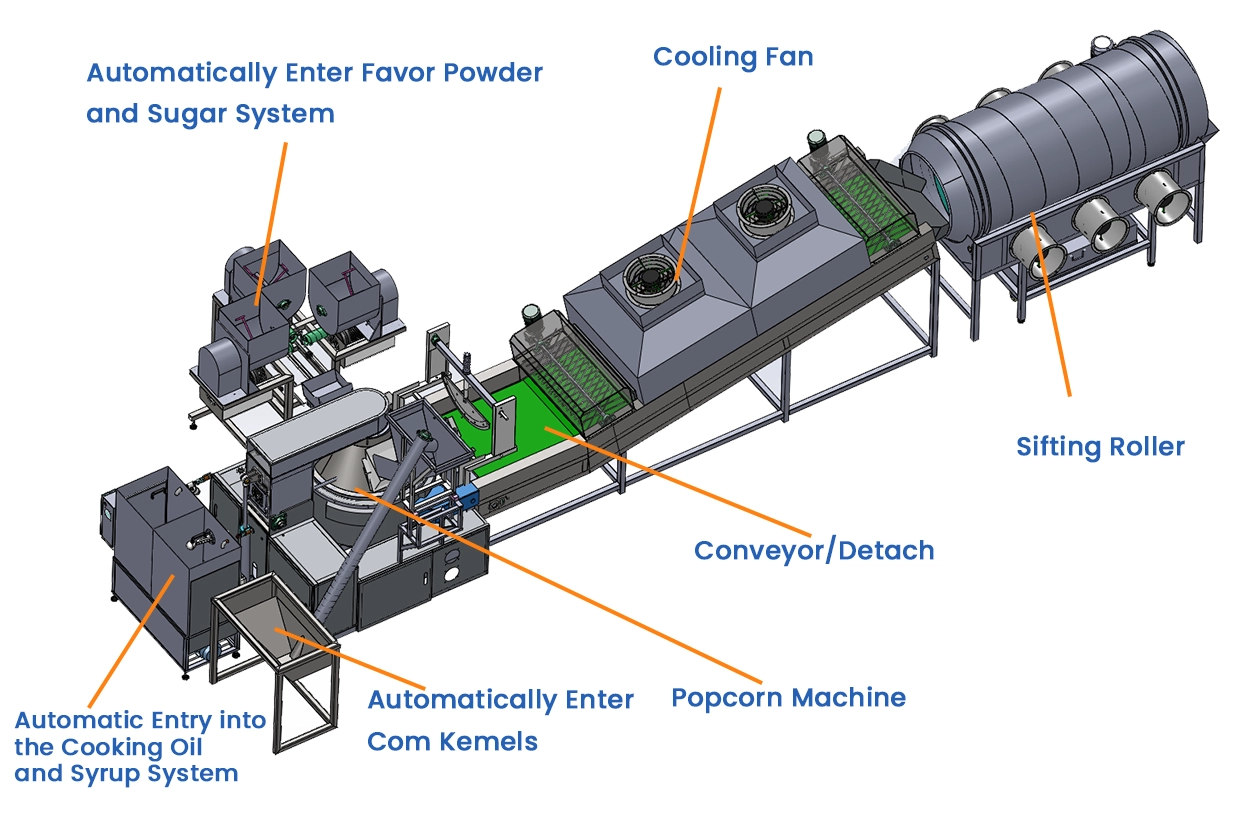

3.Tailored Production Lines

Scale your output with our modular popcorn production lines:

| Production Line Length/m | 7m | 9m | 10m | 14m |

| Popcorn Machine/set | 1set | 2set | 3set | 4-5set |

Each line includes:

Conveyor Belt: Transfers popcorn seamlessly between stages.

Popcorn Dispersion Unit: Separates clumped popcorn for uniform texture.

Cooling Fan: Rapidly reduces temperature to prevent sticking.

Screening Drum: Removes unpopped kernels for premium quality control.

Key Features for Global Clients

1.Customization: Adapt machines to your specific product requirements (e.g., shape, flavor, output).

2.Hygienic Design: Easy-to-clean surfaces and food-grade stainless steel materials meet international safety standards.

3.Automation: Reduce labor costs with fully integrated systems for popping, cooling, and screening.

4.Advanced Control System: Fully automatic operation with German Siemens PLC system or user-friendly control panel for precise programming and reliability.

5.Planetary Mixing Technology: Ensures even heat distribution and prevents burning or sticking for consistently perfect popcorn.

6.Premium Drive System: Equipped with famous brand gear motor reducers for silent, maintenance-free, and efficient performance.

7.Direct Flavor Integration: Produce seasoned, savory, or caramel popcorn directly in the machine—no additional coating equipment required.

8.Robust Construction: Engineered for 24/7 continuous operation with durable components to minimize downtime and maximize productivity.

Maximize your popcorn production with our high-capacity, flavor-ready machines. Whether you need a 100L gas popcorn machine for traditional processing or a 200L electric popcorn machine for high-volume output, our solutions ensure efficiency and quality. Explore our customizable production lines to find the perfect fit for your business.

Call to Action

Ready to boost your popcorn production? [Contact us] for a customized quote or request a demo of our automatic industrial popcorn machines today!