High-Performance Popcorn Machines for Industrial Use

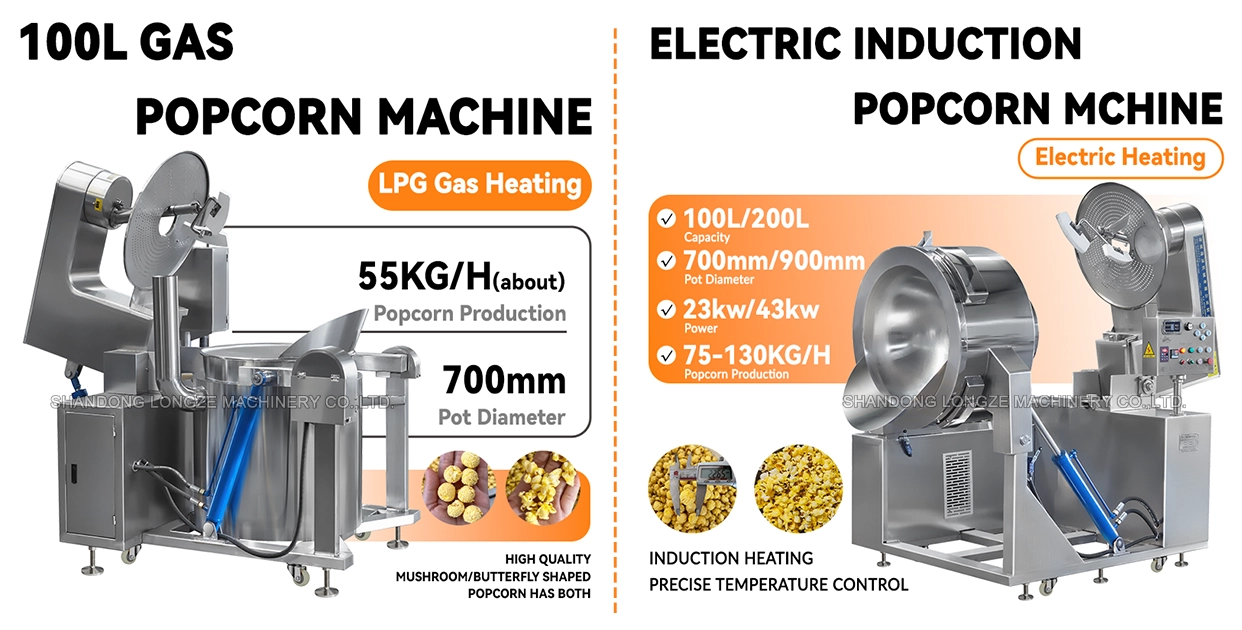

Our popcorn machine is equipped with top-tier popcorn machines featuring dual heating methods:

- Gas Heating 100L Popcorn Machine:

Produces up to 55 kg of popcorn per hour, ideal for continuous large-volume production with quick heat response. - Electric Induction Heating 100L/200L Popcorn Machines:

Generate 75 kg/hr and 130 kg/hr respectively, suitable for different capacity needs and consistent performance.

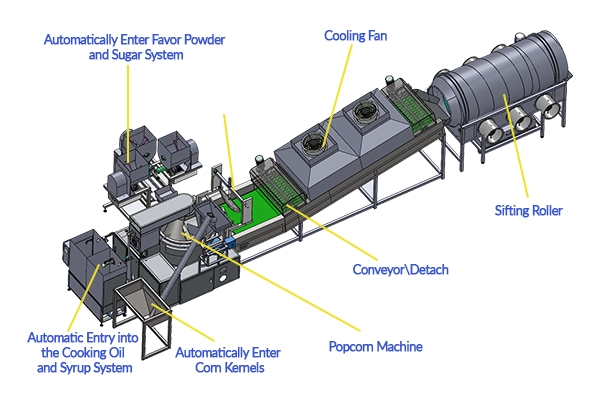

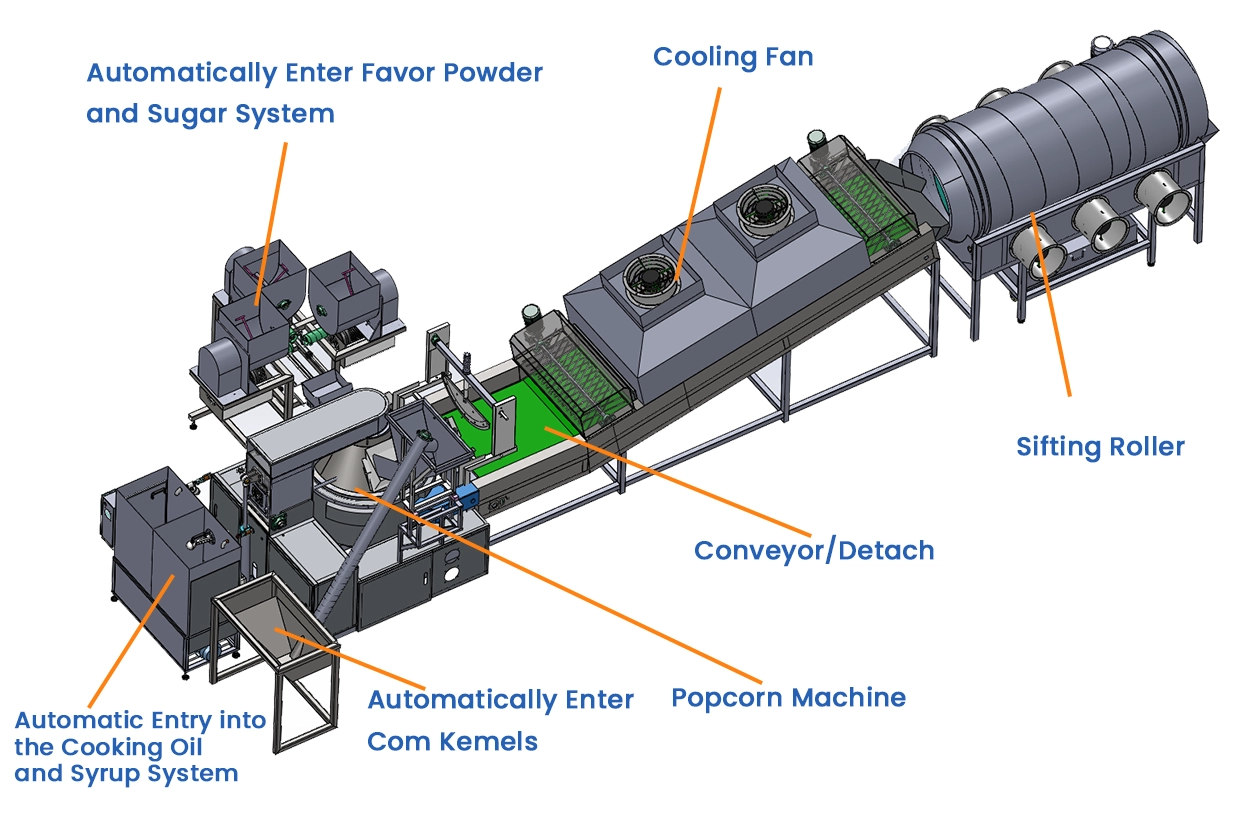

All machines utilize oil popping technology, allowing the production of popcorn with any flavor without the need for secondary coating machines. This innovative design simplifies the process, saving time and reducing equipment costs. We also have popcorn production line for you to choose.The popcorn production line consists of four parts: Conveyor, Detaching, Cooling, and Sifting Roller.

Technical Parameters

| Model | Heating Method | Capacity(Customizable) | Output/Hour | Best For |

| LZ-RQB-100L | Gas | 100L | 55kg | Startups, low-energy-cost regions |

| LZ-DCB-100L | Electric Induction | 100L | 75kg | High-volume retail, mid-size factories |

| LZ-DCB-200L | Electric Induction | 200L | 130kg | Large processing plants, OEM supply |

| We also have popcorn production line for you to choose. The shortest production line is 7 meters which can accommodate one popcorn machine. 9 meters can accommodate 2 units. 10 meters can accommodate 3 units. 14 meters can accommodate 4-5 units.The popcorn production line consists of four parts: Conveyor, Detaching, Cooling, and Sifting Roller.(After these four steps, the popcorn can be packaged directly) | ||||

*All models feature direct oil-popping technology and SUS 304 stainless steel construction.*

Advantages of Our Industrial Caramel Ball & Butterfly popcorn machine

1.High Efficiency & Productivity:

Capable of continuous operation, producing large quantities of caramel popcorn daily to meet market demand.

2.Versatile Flavor Customization:

Direct oil popping means you can add caramel, chocolate, cheese, or any flavor right after popping.

3.Intelligent Automation:

From popping to flavoring and packaging, our popcorn machine offers fully automated controls for consistent product quality.

4.Easy Operation & Maintenance:

Designed with user-friendly interfaces for quick learning and minimal downtime.

5.Energy-Saving & Durable:

Equipped with reliable heating technology that minimizes energy costs and maximizes lifespan.

Our Comprehensive Services

Pre-Sales Service:

Free Equipment Consultation: Our experts provide detailed advice to help you choose the right machinery.

Standard Equipment and Process Flowcharts: We offer detailed diagrams to illustrate efficient production setups.

Free Trial Run Service: Test the machines using your specific production process to verify product quality and performance.

Customized Solutions & Free Design: Based on your unique requirements, we develop tailored plans and assist in selecting the most suitable equipment.

During-Sales Service:

Factory Layout Design Assistance: We offer professional recommendations and provide free factory layout engineering drawings to optimize your space.

Factory Tour Invitation: Welcome to visit our manufacturing plant to see the equipment firsthand.

Equipment Inspection: Prior to delivery, all machines undergo thorough testing to ensure quality and functionality.

After-Sales Service:

Overseas Installation & Debugging: We provide professional installation and commissioning services at your site.

Operator Training: Customers can send your frontline operators to our factory for hands-on training on machine operation, maintenance, and troubleshooting.

Basic Recipe Support: We offer essential recipes to help you produce consistent, high-quality caramel popcorn.

English Operation Manuals & Maintenance Guides: Complete operational, maintenance, and troubleshooting manuals are provided in English.

Lifetime Free Maintenance & Remote Support: We are committed to lifelong support, offering free maintenance and remote guidance for troubleshooting and upgrades.