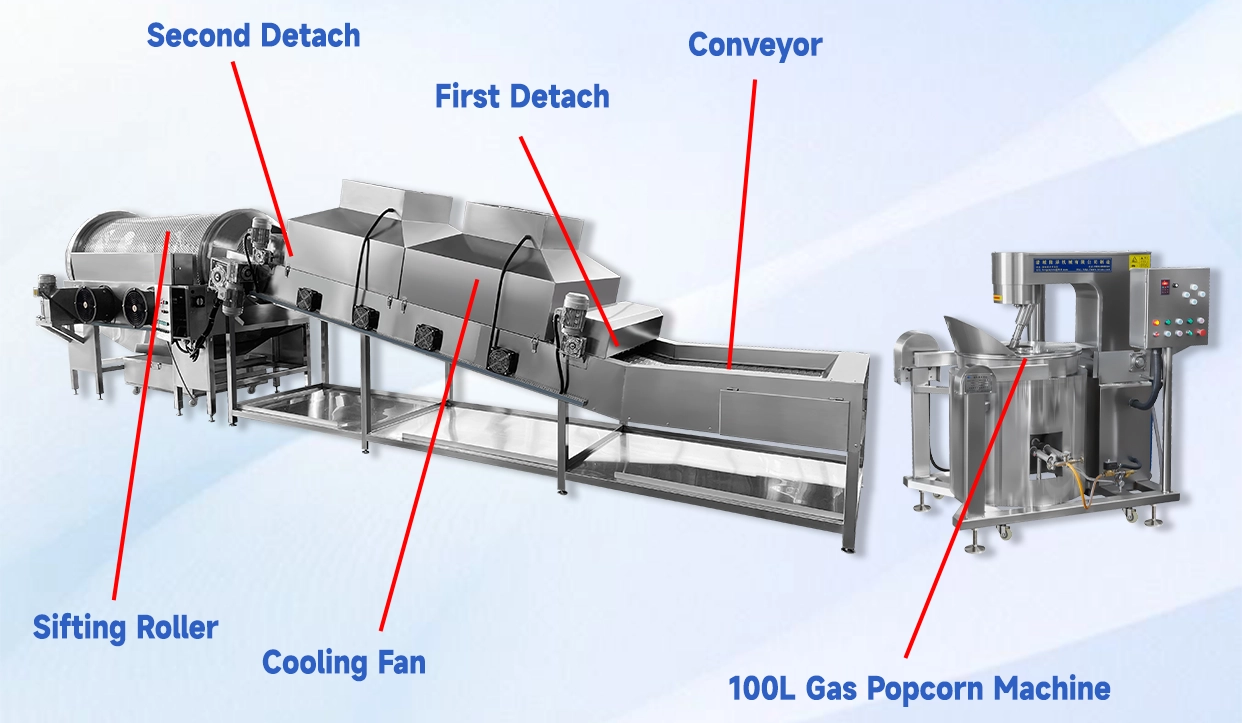

Our 100L Gas-Powered Popcorn Line revolutionizes large-scale production with a fully integrated 7-meter automated system. Centered on a diameter 700mm industrial popcorn machine (output: 55kg/h), this turnkey solution processes raw kernels into ready-to-pack popcorn through 5 optimized stages. Watch it in action below!

Why Food Producers Choose Gas Popcorn Systems

* 30% Faster Heating vs. electric machines: Consistent kernel popping at optimal temperatures

* Labor-Saving Automation: From cooking to packaging-ready output in 1 integrated line

* Scalable for High Demand: Stack multiple popcorn machine + extend conveyors for 100kg+/h capacity

How Our 100L Gas Popcorn Line Works

Phase 1: Precision Cooking

– 100L Industrial Gas Popcorn Machine

700mm Large Popcorn Machine: Even heat distribution for 98% popping rate

Gas Efficiency: 30% lower operating costs than electric models

Accomplish Popping Mixing Coating 3 in 1: Our oil-popping popcorn machine produces any flavor directly, eliminating the need for a separate coating machine, can be tilted to pour out the popcorn.

Phase 2: Automated Flow & Quality Control

– Conveyor Transfer

Food-grade belt gently moves popcorn to prevent breakage

– Separation device (first time)

Breaks clumps

– Cooling fan

Rapid cooling reduces moisture → Extends shelf life + maintains crispness

– Separation device (second time)

Breaks clumps

– Vibrating Screening Drum

Filters unpopped kernels → <2% defect rate