What is a Steam Jacketed Cooking Kettle with Mixer?

This specialized equipment consists of a high-quality stainless steel inner cooking vessel surrounded by an outer jacket. Pressurized steam is introduced into the sealed jacket space, transferring heat uniformly through the inner wall to the product. Simultaneously, a centrally mounted anchor-style agitator rotates, ensuring the contents are blended continuously. This dual-action of indirect steam heating and mechanical mixing prevents scorching, promotes even cooking, and guarantees batch-to-batch consistency.

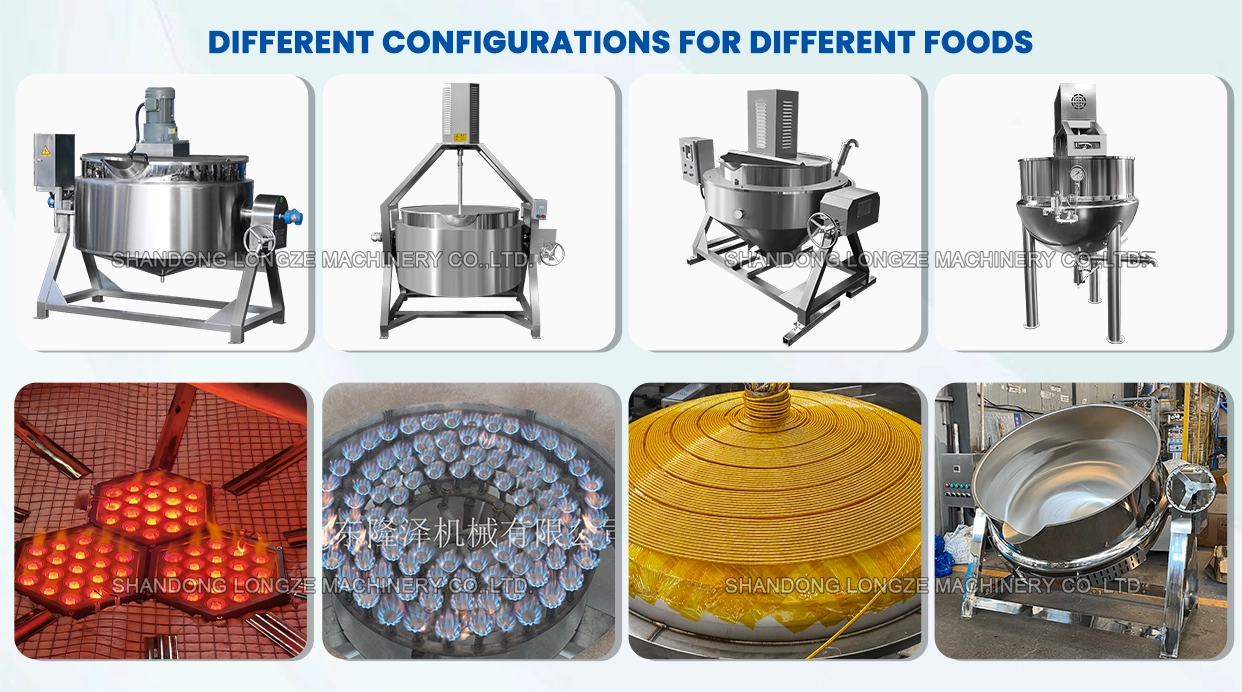

Why Choose Our Steam Jacketed Mixing Kettle for Your Processing Line?

Our kettles are engineered beyond basic functionality. We focus on the details that impact your bottom line: product quality, operational safety, and total cost of ownership.

1.Engineered for Superior Performance & Hygiene

The heart of our kettle is its food-grade stainless steel construction. The polished, seamless interior surface prevents food particle adherence and allows for thorough, rapid cleaning, meeting the stringent hygiene protocols of the food, dairy, and beverage industries. The robust anchor agitator is designed to handle viscous products effectively, ensuring no dead zones during mixing.

2.Precision and Control for Perfect Results

Gone are the days of guesswork. Our jacketed cooking kettles provide precise temperature management via regulated steam input. This control is vital for processes like candy making or sauce reduction, where specific temperature curves must be followed. The optional PLC automation package can store recipes, further enhancing repeatability and reducing operator error.

3.Built to Last with Operator in Mind

Durability is non-negotiable. We use reinforced materials and expert welding to withstand daily industrial use. Ease of use is also paramount. Many models feature a tilting body (powered by hydraulic or electric systems) for complete, easy product discharge. All controls are grouped ergonomically, and maintenance points are easily accessible.

Technical Specifications & Common Applications

| Heating Method | Gas/Electric Induction/Steam/Thermal Oil | |||||||

| Pot Diameter | 700mm | 800mm | 900mm | 1000mm | 1100mm | 1200mm | 1300mm | Customizable |

| Loading Capacity | 100L | 200L | 300L | 400L | 500L | 600L | 700L | Customizable |

| Stirring Power | 1.5kw/2.2kw/3kw/3.7kw/5kw | |||||||

| Control Method | Agitator/Bottom Discharge/PLC Programming/Temperature Control/Lid/High Pressure Water Gun/Automatic Discharge | |||||||

Industries & Applications

Food Processing: Cooking sauces (pasta, pizza), soups, stews, jams, and meat fillings.

Confectionery: Melting chocolate, dissolving sugar for syrups, cooking candy bases.

Dairy: Preparing custards, puddings, and cheese sauces.

Bakery & Beverage: Making fruit fillings, concentrates, and brewing ingredients.