What is an Industrial Biryani Cooking Mixer?

An industrial biryani mixer is a robust, jacketed cooking kettle that automates the entire process. It precisely controls temperature and mixing action to perfectly cook rice, meat, and spices together. Key benefits include:

* Consistent Quality & Taste: Every batch is identical, building your brand’s reputation.

* Massive Efficiency: Cook hundreds of liters in a single cycle, slashing labor costs and time.

* Superior Hygiene: Made from food-grade stainless steel with easy-clean designs.

* Precise Control: Digital temperature controls ensure perfect cooking every time.

An automatic cooking mixer eliminates these issues by combining precise temperature control, uniform stirring, and hands-free operation—all while replicating the traditional dum cooking technique.

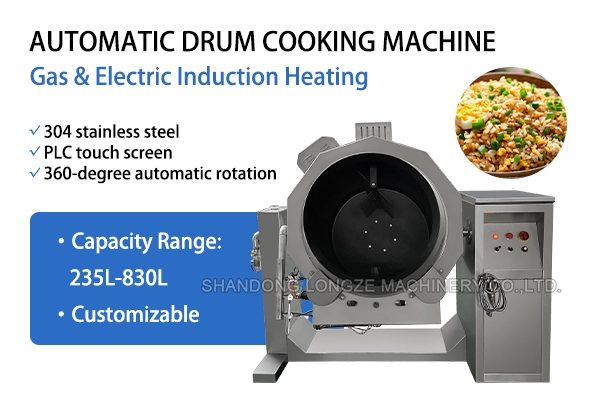

Key Features of Our Biryani Making Cooking Mixer

We’ve engineered this machine to fit diverse biryani production needs, with customizable options for heating, stirring, and capacity.

1. 4 Heating Methods: Match Your Kitchen’s Needs

Different biryani recipes and kitchen setups demand different heating solutions. Our mixer offers four industry-proven options:

| Heating Method | Advantage for Biryani Production | Ideal Scenarios |

| Gas Heating | Fast heating speed (cuts pre-heat time by 30%) for peak-hour rushes | Restaurants&Hotel & Food Processing Plant with gas supply, high-volume daily production |

| Electric Induction Heating | Precise temperature control (±1℃) for dum cooking’s low-heat stages | Facilities prioritizing energy efficiency and flavor consistency (Reminder: Induction heating must use three-phase electricity.) |

| Steam Heating | Gentle heating preserves rice texture and nutrient content | Health-focused caterers, organic food producers (A steam generator or steam boiler is required.) |

| Thermal Oil Heating | Uniform heat distribution (no hot spots) for large batches | It requires the use of heat transfer oil, has slow heat dissipation, and is suitable for continuous production. |

Pro Tip: For classic dum biryani, pair electromagnetic heating with our programmable PLC system to mimic the “low-and-slow” charcoal effect—without the smoke.

2. 2 Stirring Types: Avoid Burning & Ensure Uniformity

Biryani’s texture depends on gentle yet thorough mixing. Our two stirring systems cater to different batch sizes:

* Planetary Stirring: The agitator rotates 360° while spinning on its axis, making full contact with the pot to eliminate dead angles. Perfect for smaller batches (50L-600L) and preventing rice from sticking. Note: Only gas and electromagnetic heating models offer 50L capacity—ideal for small restaurants or test kitchens.

* Multi-Scraper Stirring: Equipped with 3-6 food-grade Teflon scrapers, this system handles high-viscosity mixtures (e.g., biryani with rich gravies) and large volumes (300L-1000L). A must for food processing plants supplying supermarkets or catering chains.

3. Customizable Capacity: 50L to 1000L

Whether you’re serving 100 customers daily or 10,000, we have a size for you:

* 50L: Small cafes, food trucks, or test batches

* 100L-600L: Mid-sized restaurants, hotel kitchens

* 300L-1000L: Large-scale food factories, bulk caterers

Technical Parameters

| Parameters | Planetary cooking mixer | Multi-scraper cooking mixer |

| Capacity | 100L-600L | 300L-1000L |

| Heating method | Gas/Electric Induction/Steam/Thermal Oil | Gas/Electric Induction/Steam/Thermal Oil |

| Power | 1.5kw/2.2kw/3kw/3.7kw/5kw | 2.2kw/3kw/3.7kw/5kw |

| Stirring speed | 0-61r/min | 0-61r/min |

| Occupancy area | 3.7-9.2㎡ | 6.5-12㎡ |

| Single batch output | 50-450kg | 150-800kg |

How to Choose the Right Biryani Mixer for You

Follow this 3-step guide to pick your perfect configuration:

* Assess Your Batch Size: If you need <600L batches, go for planetary stirring; >600L, choose multi-scraper.

* Check Your Energy Supply: No gas? Opt for electromagnetic heating. Need low operating costs? Steam heating (if you have a boiler).

* Consider Your Recipe: For wet biryani with lots of sauce, multi-scraper stirring prevents clumping. For dry dum biryani, planetary stirring preserves rice grains.