Our full-automatic caramel popcorn machines are designed to streamline the popcorn production process while ensuring consistent quality and flavor. Here’s what makes our machines stand out:

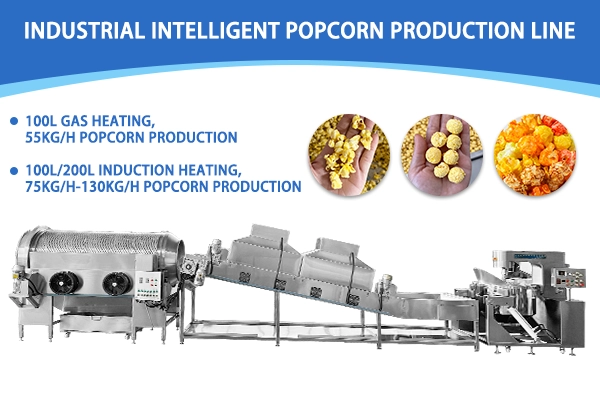

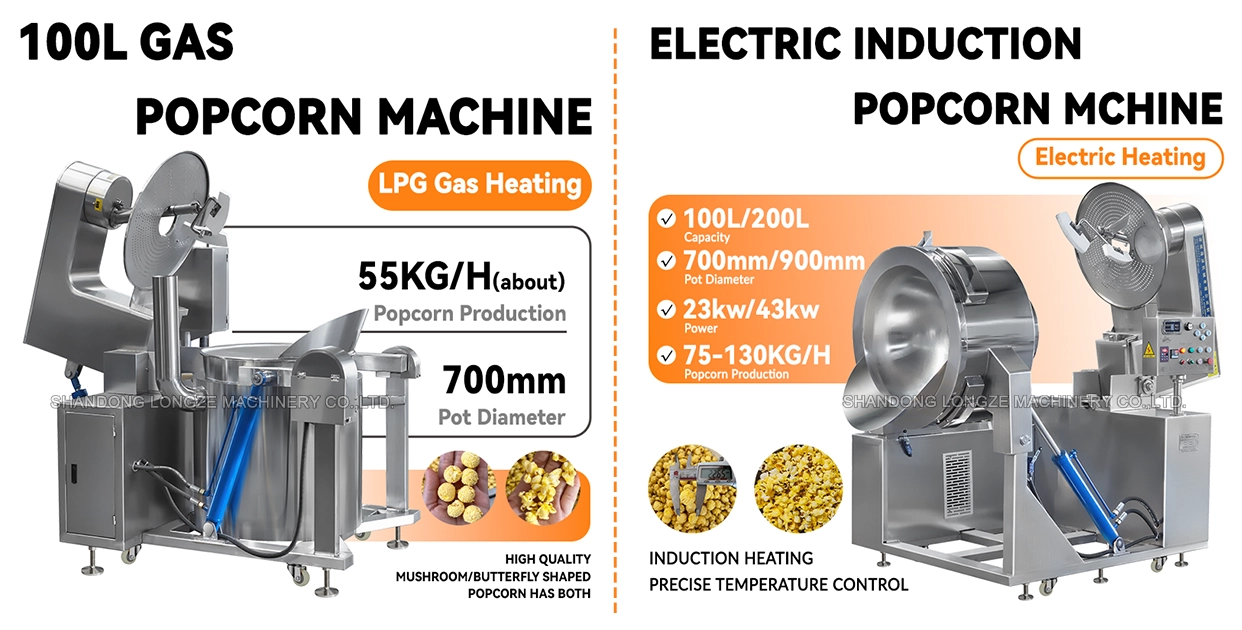

1.Heating Options & Capacities:

100L Gas Heating Popcorn Machine: Produces up to 55kg of popcorn per hour.

100L Electric Heating Popcorn Machine: Produces up to 75kg of popcorn per hour.

200L Electric Heating Popcorn Machine: Produces up to 130kg of popcorn per hour.

2.Oil-Popping Popcorn Technology:

Our machines use oil-based popping methods, which ensure even heating and perfect texture. This process allows you to produce caramel or savory popcorn directly—without the need for additional coating equipment.

Technical Parameters

| Model | Heating Method | Capacity(Customizable) | Output/Hour | Best For |

| LZ-RQB-100L | Gas | 100L | 55kg | Startups, low-energy-cost regions |

| LZ-DCB-100L | Electric Induction | 100L | 75kg | High-volume retail, mid-size factories |

| LZ-DCB-200L | Electric Induction | 200L | 130kg | Large processing plants, OEM supply |

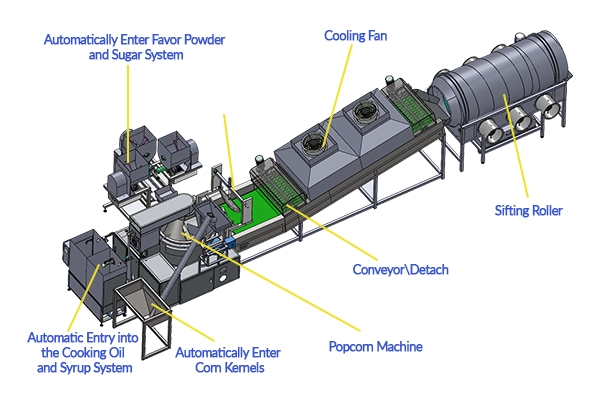

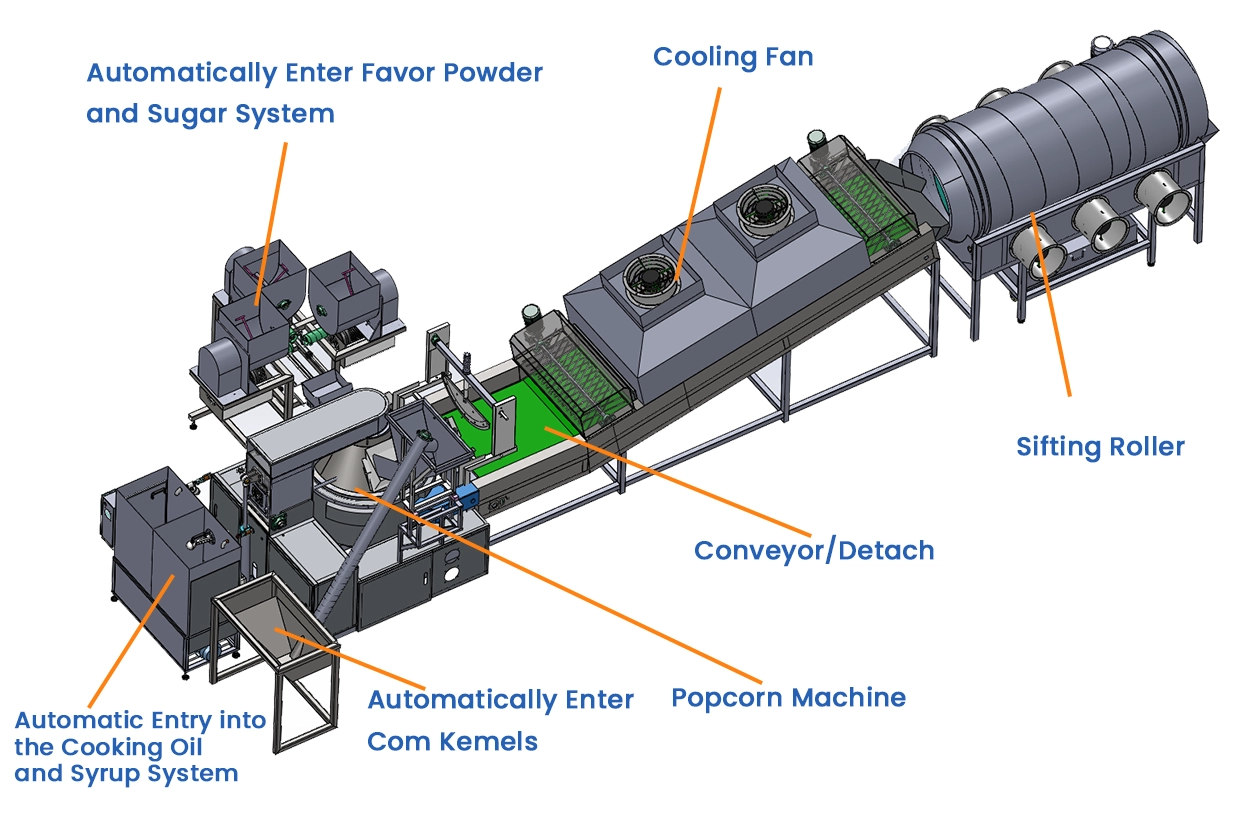

| We also have popcorn production line for you to choose. The shortest production line is 7 meters which can accommodate one popcorn machine. 9 meters can accommodate 2 units. 10 meters can accommodate 3 units. 14 meters can accommodate 4-5 units.The popcorn production line consists of four parts: Conveyor, Detaching, Cooling, and Sifting Roller.(After these four steps, the popcorn can be packaged directly) | ||||

*All models feature direct oil-popping technology and SUS 304 stainless steel construction.*

Key Features & Advantages of Our Popcorn Machine

1. Premium 304 Stainless Steel

Durable, rust-proof, and easy to clean. Complies with global food safety standards for guaranteed hygiene and long service life.

2. Planetary Mixing System

Ensures perfect, even blending from center to wall. Prevents burning and sticking for consistent flavor coverage in every batch.

3. Brand-Name Gear Reducer

Delivers quiet, smooth, and low-vibration operation. Maintenance-free design ensures long-term reliability and reduced downtime.

4. Direct Flavor Application for Popcorn

Add caramel, cheese, or custom seasonings directly into the popcorn machine. Achieves even distribution in a single step, eliminating the need for extra equipment and saving time.

5. 24/7 Continuous Operation

Built for heavy-duty production cycles. Engineered for non-stop operation to reliably meet high-volume demands and tight deadlines.

6. Automated Control Panel

User-friendly PLC allows full automation. Set custom time, speed, and temperature to reduce labor costs and ensure batch-to-batch consistency.

7. Energy-Efficient Heating

Choose electromagnetic heating for fast, efficient performance or reliable gas heating for areas with limited electrical supply.

8. Safety & Easy Maintenance

Features integrated safety protocols and a simple-to-access design for effortless cleaning and routine maintenance.

Our Services

1.Customized Solutions:

We can tailor the machine’s capacity, heating method, and features to match your production needs.

2.Global Shipping & Installation Support:

We serve clients worldwide and provide installation guidance and training.

3.After-Sales Service:

Comprehensive warranty and technical support.

Spare parts readily available for quick maintenance.

4.OEM/ODM Services:

We welcome partnerships for custom branding and machine modifications.