What is a Fully Automatic Cooking Mixer Machine?

A fully automatic cooking mixer machine is an all-in-one industrial cooking system designed to cook, mix, stir, scrape, and blend various food products with minimal human intervention. It replaces traditional, dangerous open kettles by providing a closed, controlled, and automated environment. From frying vegetables for thousands to preparing delicate sauces and reducing liquids, this machine is the backbone of a modern, scalable food operation.

Key Features & Benefits: Why Choose Our Machine?

Our cooking mixers are built with precision and versatility in mind, offering features that directly address the pain points of commercial kitchens.

Planetary Stirring:

Mimics the motion of a hand mixer but on a massive scale.This ensures every part of the kettle is reached, making it ideal for thick, viscous products like heavy sauces, pastes, mashed potatoes, and fillings that require intense, homogeneous mixing.

Four Flexible Heating Options:

Gas Heating: Provides instant, high heat familiar to most chefs, ideal for traditional wok-style stir-frying.

Electromagnetic (Induction) Heating: Offers extremely high thermal efficiency and precise temperature control. The heating surface remains cool to the touch, enhancing safety and making cleaning easier.

Steam Heating: A gentle and uniform heating method, perfect for temperature-sensitive products like dairy, delicate sauces, and melting chocolate without the risk of scorching.

Thermal Oil Heating: Delivers very high and stable temperatures for tasks requiring extreme heat, such as deep frying, caramelization, and confectionery production.

Full Automation & Programmable Control: The integrated PLC system allows you to pre-set cooking parameters (time, temperature, stirring speed). Once a program is initiated, the machine operates hands-free, eliminating human error and guaranteeing the same perfect results batch after batch.

Robust Construction & Safety: Built from high-grade, food-grade stainless steel (304/316), our machines are durable, corrosion-resistant, and meet international hygiene standards. Safety features include automatic lid locking, overflow prevention, and emergency stop functions.

Customization: We provide customized solutions based on your product output, material properties, and production process.

Hygienic Design: Easy-to-clean surfaces and food-grade stainless steel materials meet international safety standards.

Premium Drive System: Equipped with famous brand gear motor reducers for silent, maintenance-free, and efficient performance.

Robust Construction: Engineered for 24/7 continuous operation with durable components to minimize downtime and maximize productivity.

Technical Specifications at a Glance

| Parameters | Planetary cooking mixer |

| Capacity | 100L-600L |

| Heating method | Gas/Electric Induction/Steam/Thermal Oil |

| Power | 1.5kw/2.2kw/3kw/3.7kw/5kw |

| Stirring speed | 0-61r/min |

| Occupancy area | 3.7-9.2㎡ |

| Single batch output | 50-450kg |

| Control methods | Button/PLC Touch Screen/Remote Control/AIO Control |

| Optional configuration | Automatic Weighing/Metering Pump/High Pressure Water Tap/Water Pipe/Oil Filling Pipe/Temperature Control |

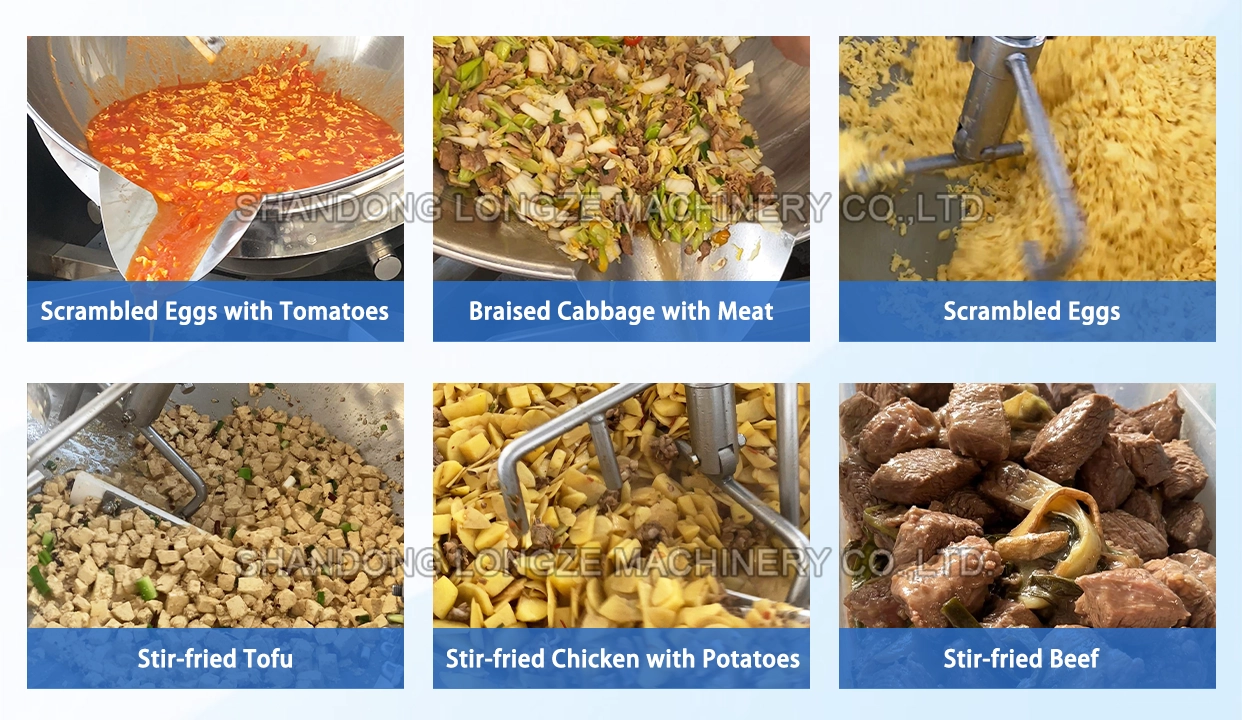

Versatile Applications: What Can It Cook?

This is not just a mixer; it’s a multi-functional cooking center capable of handling an astonishing variety of tasks:

Savory Dishes: Stir-frying vegetables, cooking rice, making stews, and preparing large batches of curry.

Sauces & Condiments: Producing ketchup, mayonnaise, pasta sauce, and all types of dressings.

Sweet Preparations: Cooking jam, jelly, pie fillings, caramel, nougat, and chocolate.

Liquid Reduction: Concentrating juices, milk, and soups.

Other Uses: Sugar coating for nuts, mixing powder blends, and much more.

FAQ

Q1: Why chooses LONGZE machinery?

A1:*We have more than 14 years experience in manufacturing food processing machines, more specialized in bulk production.

*More professional team in purchasing, producing, sales and technology, with excellent equipments.

*Have fast after-sales service.

Q2: How long is your delivery time?

A2: Generally, it will take 15 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3: How does your factory do in terms of quality control?

A3: Quality is priority.We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

Investing in a fully automatic cooking mixer machine is an investment in the future of your food business. It drastically reduces labor costs, improves product quality and consistency, enhances food processing factory and kitchen safety, and boosts your overall production capacity.

Ready to transform your product production model? Contact our experts today for a free consultation and a personalized quote. We will help you choose the perfect model, capacity, and heating method tailored to your specific production needs. Let us help you cook smarter, not harder.