How to Produce Perfect Caramel Sauce at Scale with a Fully Automatic Cooking Mixer

The Challenge of Large-Scale Caramel Production

Caramel sauce is a beloved ingredient in desserts, beverages, and confectionery. However, scaling its production from a kitchen recipe to an industrial level presents significant challenges: precise temperature control to prevent burning, consistent stirring to avoid crystallization and scorching, and efficient, reproducible batches to meet high demand.

For food manufacturers worldwide, achieving perfect caramel sauce every time is not just an art—it’s a science that requires advanced equipment. This is where a fully automatic cooking mixer becomes an indispensable asset for your factory.

Why a Fully Automatic Cooking Mixer is Ideal for Caramel Sauce

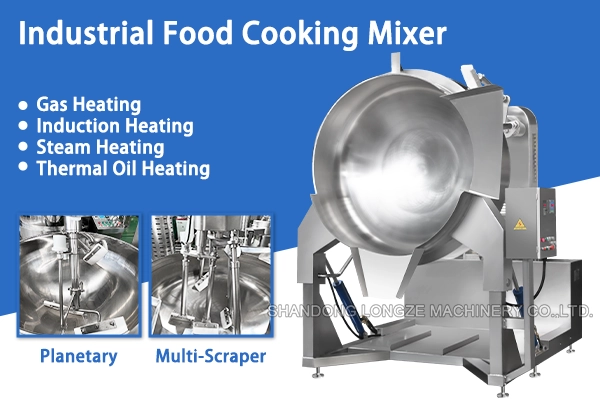

Traditional open-kettle methods are labor-intensive, risky, and inconsistent. An industrial cooking mixer solves these problems with:

Precise Temperature Control: Automated heating systems maintain the exact temperature curve needed for caramelization, eliminating guesswork and burning.

Homogeneous Mixing: Powerful yet gentle agitation ensures every sugar particle melts evenly and ingredients like butter, cream, and vanilla are perfectly emulsified.

Scalability: Produce from 50L to 1000L of consistent, high-quality sauce in a single batch.

Safety & Automation: Closed systems reduce the risk of burns for operators. Automated programs allow for one-touch operation, ensuring batch-to-batch consistency.

Efficiency: Integrated heating and mixing significantly reduce production time compared to traditional methods.

How Our Cooking Mixer Perfects the Caramel Sauce Process

The journey from sugar to silken sauce is meticulously managed by the machine’s automation.

Loading & Melting: Granulated sugar is loaded into the cooking mixer machine. The program initiates gentle heating (using the chosen heating method) and slow stirring to melt the sugar evenly without creating hot spots that lead to crystallization.

Caramelization – The Critical Phase: Once melted, the temperature is precisely raised to the caramelization stage (typically between 170°C – 180°C / 338°F – 356°F). The mixer’s sophisticated PLC control system holds this temperature with pinpoint accuracy, ensuring perfect color and flavor development without burning.

Incorporating Ingredients: The hot, melted sugar is then carefully cooled to a specific temperature by stopping the heating process. Warm dairy ingredients (butter, cream) are then gradually added. Our mixers provide precise speed and motion control, allowing for a smooth and thorough integration of all components without aeration or splashing, which is essential for a consistent product texture.

Unloading: Once the batch is complete and has reached the desired consistency, the fully automatic hydraulic tilting system safely and effortlessly pours the finished caramel sauce into waiting containers or transport vessels for further handling and packaging. This eliminates manual lifting, reduces strain on operators, and minimizes the risk of burns.

Choosing the Right Cooking Mixer for Your Caramel Sauce Operation

Not all cooking mixers are the same. The best choice depends on your required capacity and desired product texture.

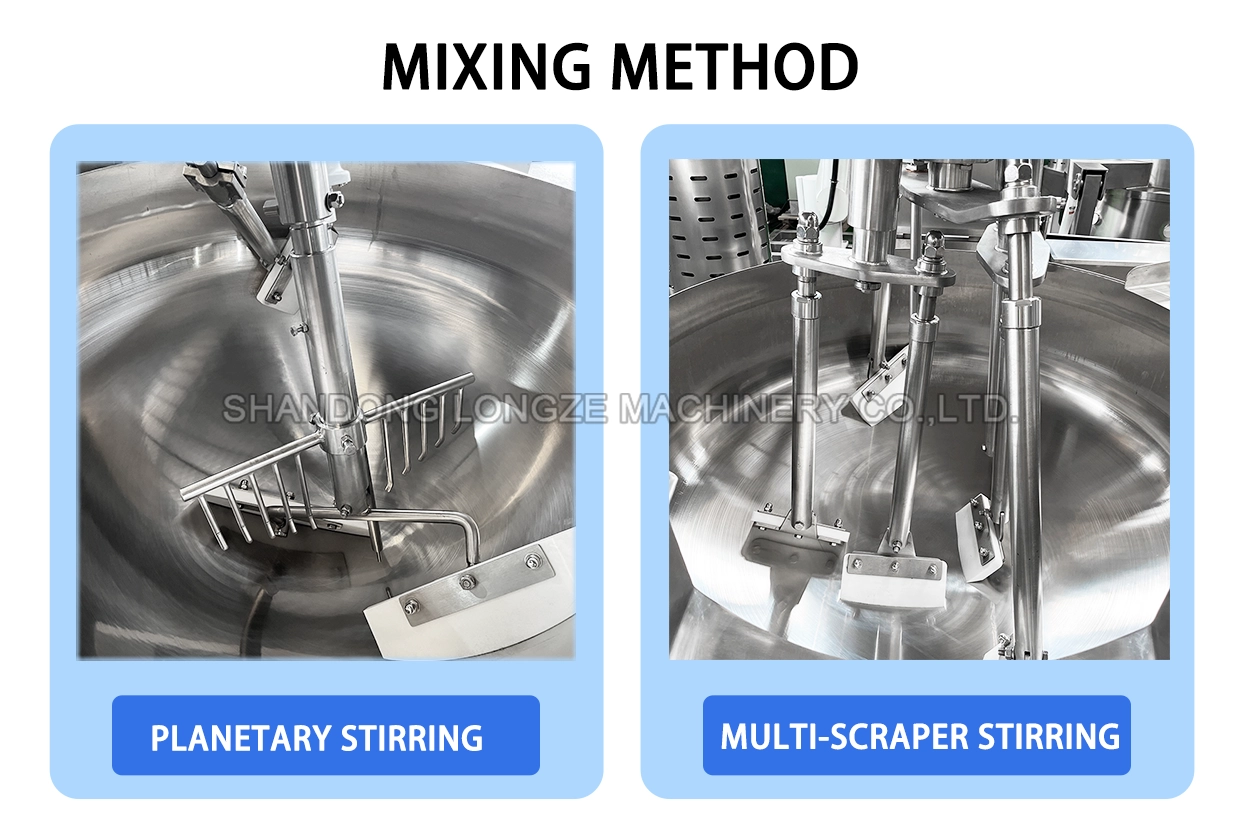

| Feature | Planetary Stirring Mixer | Multi-Scraper Stirring Mixer |

| Best For | Thicker sauces, denser products, precise mixing | Extremely viscous products, preventing sticking |

| Capacity Range | 50L(Gas,Electric Induction), 100L, 200L, 300L, 400L, 500L, 600L | 300L, 400L, 500L, 600L, 700L, 800L, 900L, 1000L |

| Stirring Action | The agitator rotates on its axis while orbiting the bowl, ensuring no dead zones. | Multiple scrapers closely conform to the bowl’s contour, continuously scraping the sides and bottom to prevent scorching. |

| Ideal Heating | Induction Heating (for fastest, most precise temp control), Gas Heating, Steam Heating (for gentle, even heat) or Thermal Oil Heating (for very high temperatures) | |

Recommendation: For caramel sauce, a Planetary Mixer with Induction Heating is often the preferred choice for capacities up to 600L due to its exceptional control and efficiency. For the largest batches (800L-1000L) where preventing scorching on the large surface area is paramount, a Multi-Scraper Mixer with Thermal Oil Heating is unbeatable.

Key Benefits of Our Automatic Cooking Mixers for Sauce Production

Four Heating Options: Choose the perfect method for your factory’s setup and product needs:

* Induction Heating: Extremely fast, energy-efficient, and offers superior precision.

* Gas Heating: Traditional, cost-effective, and powerful.

* Steam Heating: Gentle and even, ideal for temperature-sensitive products.

* Thermal Oil Heating: Achieves and maintains very high temperatures consistently, perfect for large-scale caramelization.

Programmable Logic Control (PLC): Store countless recipes (for caramel, chocolate, jam, etc.) for one-touch, error-free operation.

Sanitary Design: Made with high-quality stainless steel (SS304/SS316), polished surfaces, and easy-clean features to meet international food safety standards.

Customization: We can tailor the machine’s capacity, heating power, and automation features to your specific production line.

Call to Action

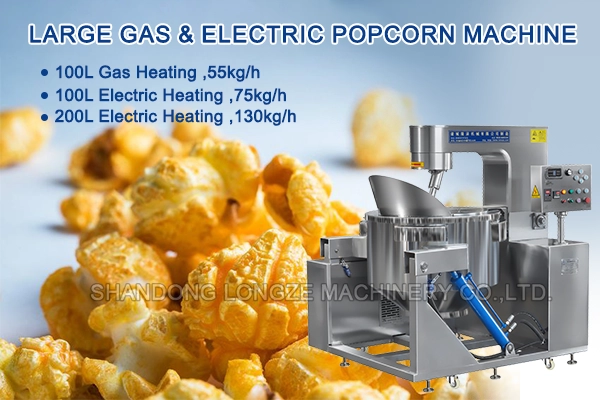

Ready to boost your popcorn production? [Contact us] for a customized quote or request a demo of our automatic industrial popcorn machines today!