1. Oil – Popping Popcorn Technology

Our popcorn machines adopt oil – popping methods, which have several advantages. This technique allows for the direct production of any flavor of popcorn without the need for additional flavor – coating machines. By simply adding the desired flavorings during the popping process, manufacturers can create a wide range of delicious popcorn flavors, from classic butter to exotic spices.

2. Introduction to the Popcorn Machine

Heating Methods

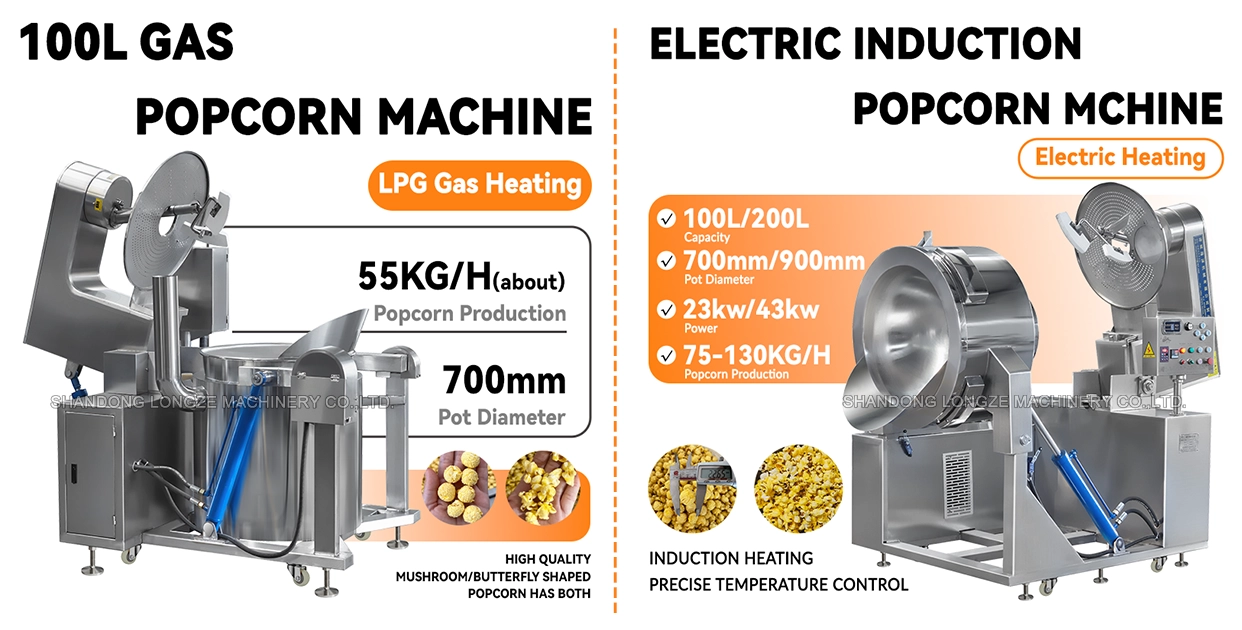

1. 100L Gas Popcorn Machine – Reliable High-Efficiency Commercial Popper

Fuel Type: Gas (LPG)

Capacity: 100L | Output: 55kg/hour

Perfect For: Cinemas, Mid-Sized Events, Snack Bars & Grocery Stores

KEY ADVANTAGES:

Unmatched Reliability: Gas heating delivers consistent, even heat distribution for perfectly popped kernels every batch

Rapid Production: A pot of popcorn can be produced in about 5 minutes, Achieve 55kg of gourmet popcorn per hour–ideal for steady mid-volume demand

Crispier Results: Direct flame technology creates golden.

Lower Operating Costs: Cost-efficient fuel consumption vs. traditional electric models

2. 100L & 200L Electric Induction Popcorn Machine – Precision High-Volume Popping

Tech: Electric Induction | Voltage: 380V

MODELS & OUTPUT:

•100L Unit: A pot of popcorn can be produced in about 3.5 minutes, 75kg/hour Premium Output

•200L Unit: A pot of popcorn can be produced in about 5.5 minutes, 130kg/hour Industrial-Grade Capacity

Perfect For: Popcoen Food Processing Factory, Mega Theaters, Amusement Parks, Stadiums & Bulk Catering

KEY ADVANTAGES:

Pinpoint Temperature Control: Electromagnetic tech enables ±1°C accuracy for 98% pop rates and zero scorching

Industry-Leading Output: Produce 75-130kg/hour–scale operations without added equipment

Consistent Quality: Smart heat distribution ensures uniformly buttery popcorn, batch after batch

Zero Preheat Time: Start production instantly with responsive electromagnetic coils

| Model | Heating Mode | Diameter | Motor Power | Stirring Speed | Discharge Type | Control Mode | Production efficiency | Overall dimensions |

| Gas | LPG | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button | 50kg/h | 1207*1500*1500 |

| Electric Induction | Electric Induction 20kw | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence | 75kg/h | 1565*1373*1606 |

| Intelligence Electric Induction | Electric Induction 40kw | 900mm | 2.2kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence/Automatic Feeding | 130kg/h | 1541*1851*1675 |

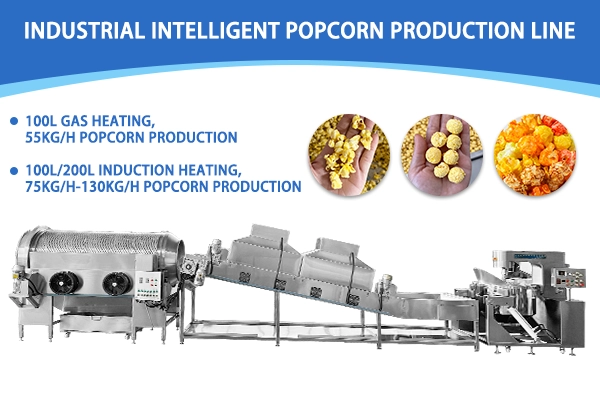

3. Introduction to the Production Line

Our popcorn production lines are highly versatile and can be customized to meet different production requirements. The length of the production line is carefully matched with the number of popcorn machines.

| Production Line Length/m | 7m | 9m | 10m | 14m |

| Popcorn Machine/set | 1set | 2set | 3set | 4-5set |

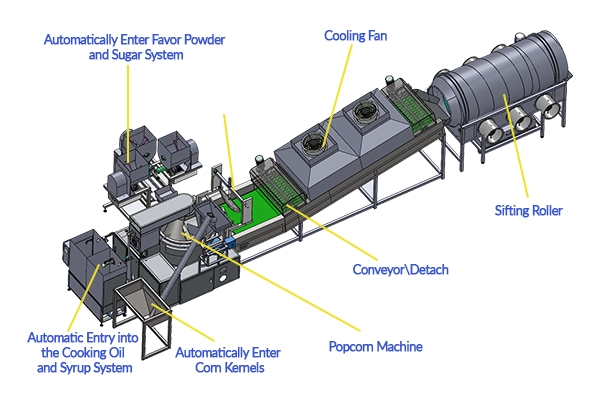

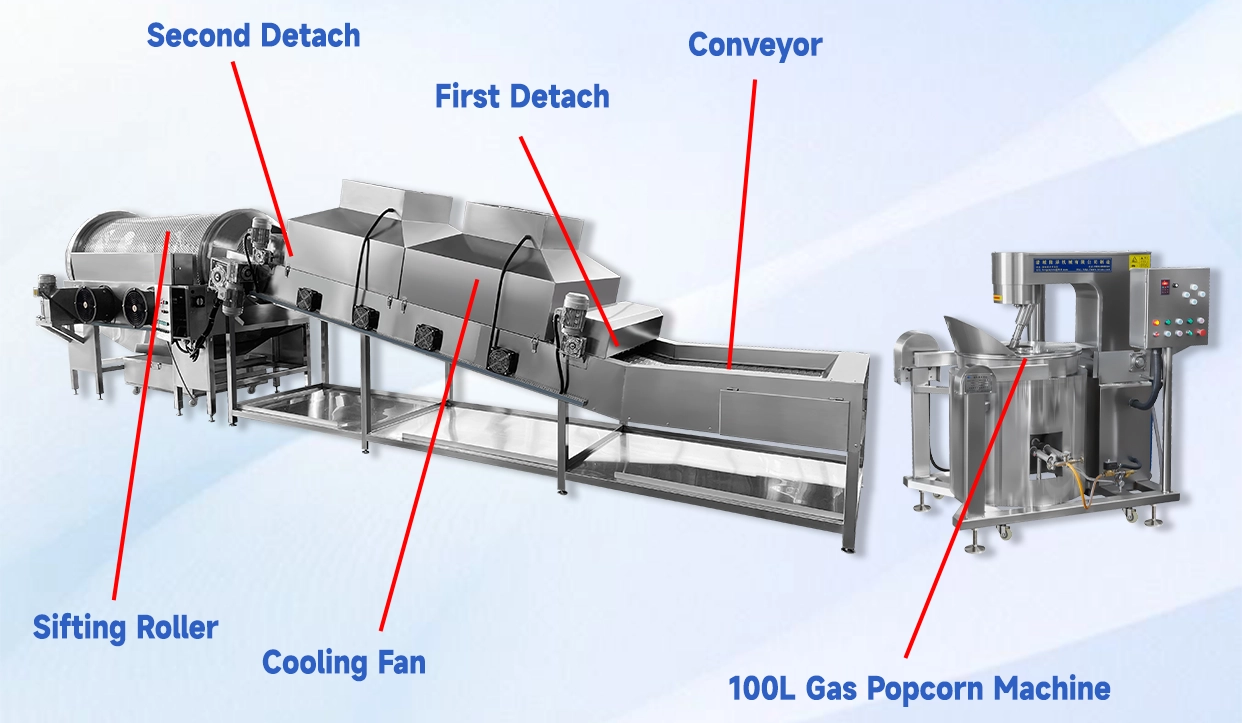

The production line consists of four main components:

1.Conveyor Belt: This component plays a crucial role in moving the freshly popped popcorn to the next stage of the process, ensuring a smooth and continuous flow of production.

2.Popcorn Dispersing Device: It effectively separates any popcorn that may have stuck together during the popping process, guaranteeing that each kernel is individual and ready for further processing.

3.Cooling Fan: The cooling fan is designed to rapidly lower the temperature of the popcorn. This is essential as it prevents the popcorn from sticking due to residual heat, maintaining its quality and texture.

4.Screening Drum: The screening drum is responsible for filtering out any un – popped corn seeds, ensuring that only high – quality, fully – popped popcorn reaches the packaging stage.

4. Advantages of the Machine

1.High Production Capacity: With our range of popcorn machines, manufacturers can significantly increase their production output. Whether it’s a small – scale operation or a large – scale industrial plant, our machines can meet the demands of high – volume production.

2.Versatility in Flavor Production: The ability to produce any flavor of popcorn directly in the machine without additional coating equipment gives our customers a competitive edge in the market. This allows for quick adaptation to changing consumer preferences.

3.Durable and Reliable: Our popcorn machines and production lines are built with high – quality 304 stainless steel materials, ensuring long – term durability and reliable operation. They are designed to withstand the rigors of continuous industrial use, reducing maintenance costs and downtime.

4.Customization Options: We understand that every customer has unique requirements. That’s why we offer customization services, allowing our clients to tailor the popcorn machines and production lines to their specific production needs, space limitations, and budget.

5. FAQ

Q1: Why chooses LONGZE machinery?

A1:*We have more than 14 years experience in manufacturing food processing machines, more specialized in bulk production.

*More professional team in purchasing, producing, sales and technology, with excellent equipments.

*Have fast after-sales service.

Q2: How long is your delivery time?

A2: Generally, it will take 15 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3: How does your factory do in terms of quality control?

A3: Quality is priority.We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

In conclusion, our commercial fully automatic popcorn machine equipment and industrial intelligent popcorn production lines offer a complete solution for popcorn manufacturers worldwide. With high – quality products, excellent service, and a commitment to innovation, we are your ideal partner in the food processing industry. Contact us today to take your popcorn production to the next level.