Burned meat sauce? Inconsistent batches? Traditional stovetop cooking wastes 40% energy and risks scorching in large batches. Discover how induction-heated planetary mixers solve commercial kitchen nightmares.

Why Food Processing Plants Choose Induction Heating Mixers for Sauces like Meat Sauce?

Food processing facilities select induction heating cooking mixers for sauce production due to critical operational advantages. Precise temperature control is achieved through 8-stage temperature settings combined with a wireless temperature probe, maintaining accuracy within ±0.5°C (±0.9°F) – essential for consistent product quality.

The zero scorching guarantee comes from the planetary mixing system. Its scraping blades thoroughly clean the bottom and sides of the mixing bowl during operation, eliminating dead zones. This is particularly crucial when processing thick, sticky sauces prone to burning.

High efficiency characterizes induction heating technology. It provides instant on/off heating directly to the cooking vessel, resulting in faster heating times and superior thermal efficiency compared to indirect heating methods.

PLC intelligent control systems enhance operational efficiency by storing 20+ process parameter sets. This enables one-touch recipe switching and remote machine monitoring/control capabilities.

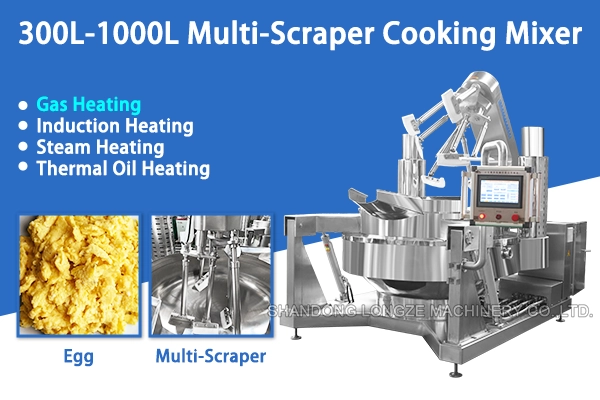

Multiple heating options – including induction, gas, steam, and thermal oil – offer installation flexibility. Plants can choose the heating method that best integrates with their existing facility infrastructure without requiring major modifications.

Invite you to watch the real meat sauce production process

Book a LIVE DEMO: Send us your toughest sauce – we’ll cook it in our mixer and send video proof!