1. Core Automation Systems: Precision Redefined

At the heart of our production line lies a suite of smart automation systems designed to eliminate variability and enhance control. Key differentiators:

- Oil-based popping technology ensures authentic texture and flavor development

- Integrated flavor infusion system produces any seasoned variety directly in-machine

- Zero need for secondary coating equipment

This end-to-end control guarantees 98% flavor consistency while reducing footprint by 40%.

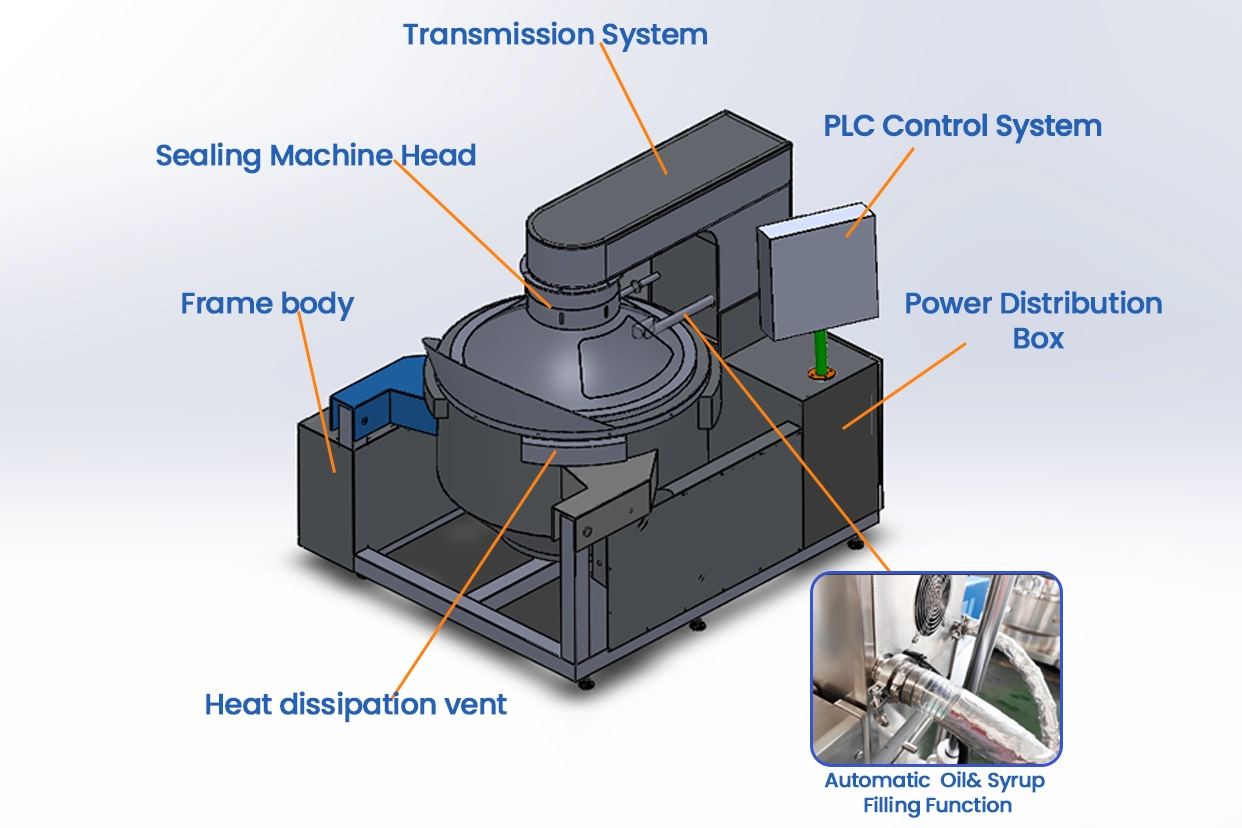

Smart Add Oil & Syrup Control System

- Sensor-Driven Precision: Automatically adjusting oil and syrup dispensing in real time. Whether crafting classic buttered popcorn or exotic flavor combinations (caramel, cheese, or spicy), this system ensures every batch delivers identical taste and texture.

- Error Elimination: By replacing manual measuring with PLC control, it reduces flavor inconsistencies by over 90% compared to traditional methods, building unwavering trust in your brand.

Precision Weighing System

- High-precision load cells (±0.1g accuracy) simultaneously measure raw corn kernels and flavor powder inputs. This dual-ingredient monitoring prevents over/under-processing while minimizing waste. Integrated with our PLC smart system, it stores 20+ preset process recipes for one-touch switching, enabling real-time material tracking, recipe optimization, and simplified inventory management.

Automatic Pot Discharge

- Hydraulic Flipping Mechanism: A hygienic hydraulic system transfers popped corn without human contact, eliminating cross-contamination risks. Complies with FDA/EU 10/2011 food safety standards.

- Labor Efficiency: Reduces manual handling by 100%, cutting labor costs by up to 60% while accelerating production flow.

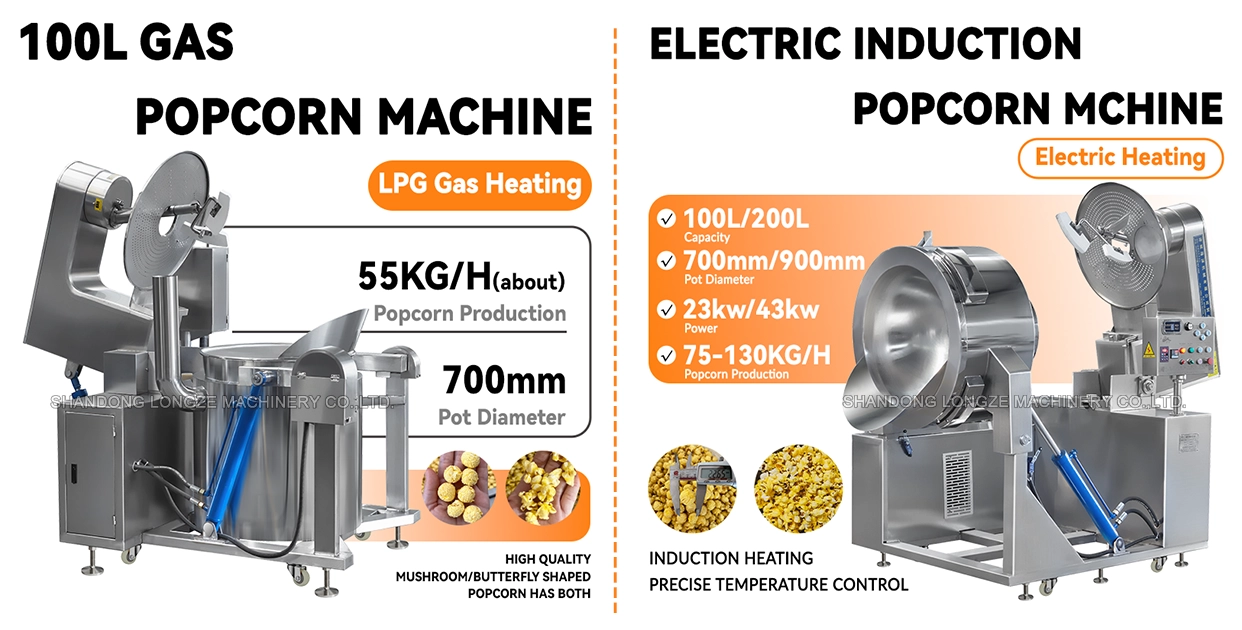

2. Dual-Heating Popcorn Machines: Flexibility for Every Need

We offer two heating options to suit varying operational requirements, ensuring optimal performance in any setting:

| Model | Heating Mode | Diameter | Motor Power | Stirring Speed | Discharge Type | Control Mode | Production efficiency | Overall dimensions | Advantages |

| Gas | LPG | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button | 55kg/h(5 minutes per batch) | 1207*1500*1500 | Cost-effective for regions with low LPG prices; suitable for medium-volume production. |

| Electric Induction | Electric Induction 20kw | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence | 75kg/h(3.5 minutes per batch) | 1565*1373*1606 | no open flames/exhaust; ideal for eco-conscious facilities. |

| Intelligence Electric Induction | Electric Induction 40kw | 900mm | 2.2kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence/Automatic Feeding | 130kg/h(5.5 minutes per batch) | 1541*1851*1675 | Highest throughput in its class; perfect for large-scale industrial production. |

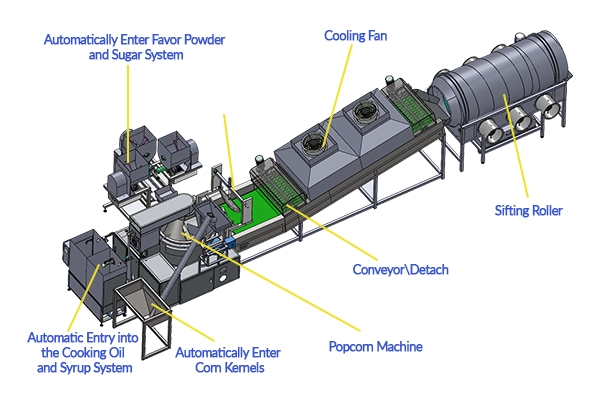

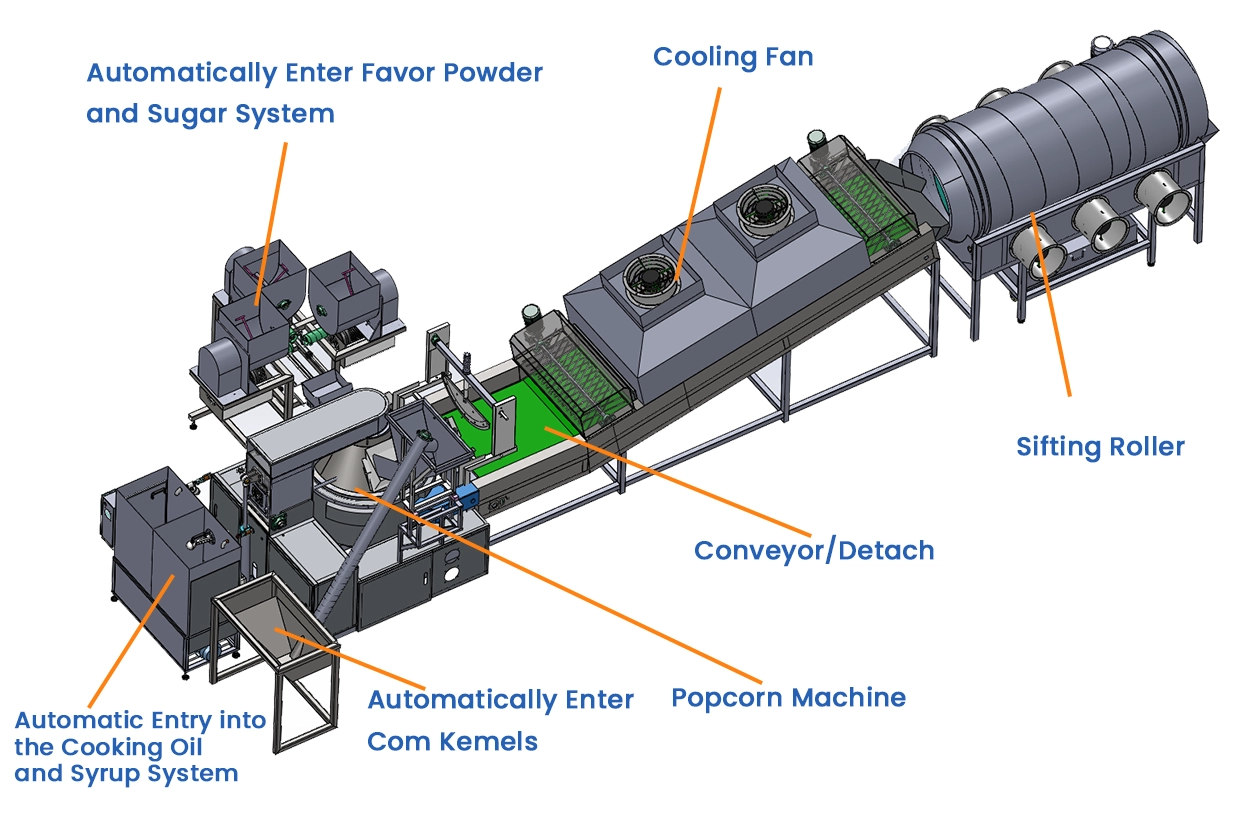

3. Optimized Production Workflow: Speed Meets Quality

Our production line combines modular components to create a seamless, high-performance workflow, adaptable to diverse production scales and demands.

| Production Line Length/m | 7m | 9m | 10m | 14m |

| Popcorn Machine/set | 1set | 2set | 3set | 4-5set |

4. Integrated Processing Modules: Streamlined Perfection

Each component in our production line works in harmony to deliver flawless popcorn, from kernel to final product:

- Variable-Speed Conveyor System: Smoothly transports popcorn between stages, with adjustable speeds (0.5–2m/s) to sync with different production rhythms—preventing bottlenecks.

- Separation device: High-speed rotating blades (adjustable RPM) gently separate clumped popcorn, ensuring each piece remains intact. The blade design adapts to popcorn size, making it suitable for both mini and jumbo kernels.

- Bellows Cooling Tunnel: Equipped with high-velocity fans and optimized air ducts, it reduces popcorn temperature from 120°C to 30°C in just 60 seconds—30% faster than conventional cooling systems. This prevents sogginess and preserves crispness, while preparing the product for immediate packaging.

- Rotary Drum Screening: A fine-mesh drum (0.5mm aperture) separates broken, misshapen, or unpopped kernels, removing 99.8% of defective products. This not only elevates quality but also reduces waste by up to 15%.

5. Why Global Manufacturers Choose Our Production Line

- Unmatched Quality Consistency: Automated systems (from ingredient dosing to screening) ensure every bag of popcorn meets the same high standards, building customer loyalty.

- Scalability for All Sizes: The line’s modular design offers flexible configurations to fit diverse space requirements, with customizable layouts suitable for both small workshops and large industrial facilities.

- Cost Savings: Reduces labor costs by 60%, cuts material waste by 15%, and electromagnetic models feature energy-efficient operation optimized for long-term production cycles. This comprehensive efficiency delivers rapid ROI.

- Compliance & Safety: Meets global food safety certifications (ISO 22000, HACCP) with features like stainless steel construction (easy to sanitize) and zero-contact processing.

Our Industrial Unmanned Fully Automatic Popcorn Production Line isn’t just a machine—it’s a strategic investment in efficiency, quality, and growth. Whether you’re a small-scale snack producer or a multinational food giant, this line transforms popcorn manufacturing from a labor-intensive process into a streamlined, profitable operation.

Ready to revolutionize your popcorn production? Contact us today for a customized quote and discover how automation can elevate your brand.