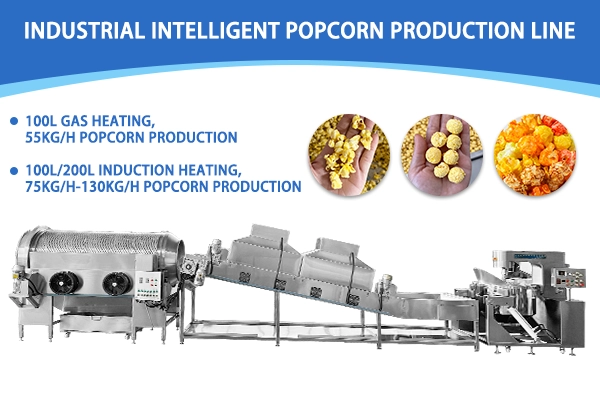

Making Popcorn with Popcorn Production Line

1. Description

Our popcorn machine uses oil popping.Our popcorn machine can produce any flavored popcorn directly,no need for other flavor coating machine.

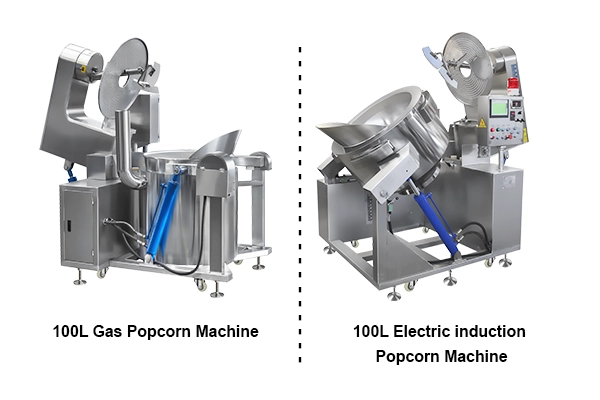

We have two types of popcorn machines, one is gas heating and the other is Electric induction heating. Gas heating is 50KG per hour,Electric induction heating is 75-130KG per hour.

If your production volume is large, we also have popcorn production lines for you to choose.The production efficiency of the production line can reach 55kg/h-650kg/h

2.Technical Data

| Model | Heating Mode | Diameter | Motor Power | Stirring Speed | Discharge Type | Control Mode | Production efficiency | Overall dimensions |

| Gas | LPG | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button | 50kg/h | 1207*1500*1500 |

| Electric Induction | Electric Induction 20kw | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence | 75kg/h | 1565*1373*1606 |

| Intelligence Electric Induction | Electric Induction 40kw | 900mm | 2.2kw | 0-80r/min | Automatically Hydraulic | Button/Intelligence/Automatic Feeding | 130kg/h | 1541*1851*1675 |

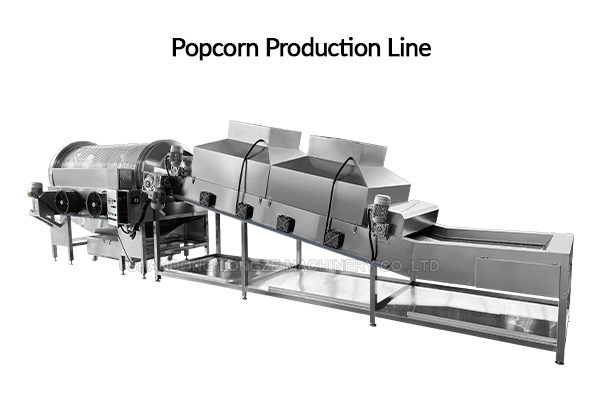

| Production Line Length/m | 7m | 9m | 10m | 14m |

| Popcorn Machine/set | 1set | 2set | 3set | 4-5set |

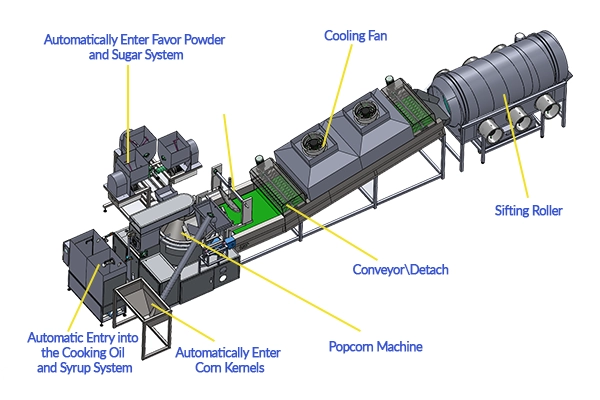

3.Structure and Features

| Popcorn Production Line | |

|  |

| Conveyor Line: Conveying Popcorn from Popcorn Machine | Detaching Device:Separating Popcorn |

|  |

| Cooling Fan: Cool Popcorn Quickly | Sifting Roller: Screening Out Unpopped Corn Seeds |

| |

| Complete Production Line:Popcorn Machine,Conveyor, Separation, Cooling, DetachingScreening | |

4.Why Choose Our Industrial Popcorn Machinery?

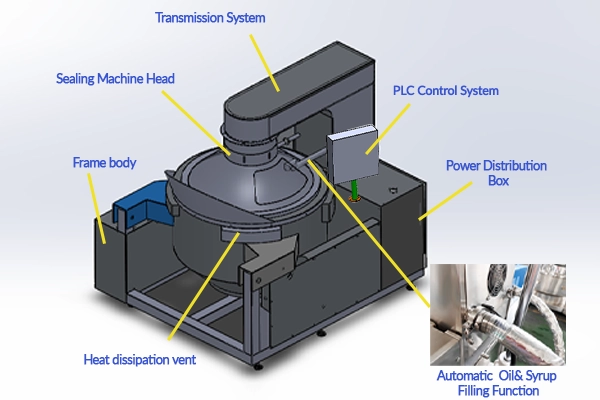

*Smart Automation for Seamless Operations

AI-Driven Control Panels: Monitor real-time parameters like temperature (±1°C accuracy).

Fully Automated Workflow: From kernel feeding to flavor coating and finished product, reduce manual intervention by 90%.

Predictive Maintenance Alerts: IoT sensors detect mechanical anomalies, ensuring ≤0.5% unplanned downtime.

*High-Capacity Production Lines

Output Range: 50kg/h to 650kg/h configurations, tailored for factories of all sizes.Achieving 24/7 operation with ≤1.5% waste rate.

*All stainless steel 304,including frame and base plates

*Fully automatic with German Siemens PLC system or control panel

*Famous brand gear motor reducer, silent mode and no need maintenance

5.FAQ

Q1: Why chooses LONGZE machinery?

A1:*We have more than 14 years experience in manufacturing food processing machines, more specialized in bulk production.

*More professional team in purchasing, producing, sales and technology, with excellent equipments.

*Have fast after-sales service.

Q2: How long is your delivery time?

A2: Generally, it will take 15 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3: How does your factory do in terms of quality control?

A3: Quality is priority.We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.