High-efficiency Industrial Automatic Curry Sauce Production Cooking Mixer Machine

1.Description

This type of cooking machine is designed and manufactured with our patents. Full body is made up of stainless steel 304, world recognized suitable and healthy steel for food materials, except for electric and hydraulic parts. All parts are fabricated in our factory with laser machines to ensure their accuracy and compatibility with each other and thus reduce occurrence of breakdown. It has been repeatedly tested in our factory to achieve its best operation and function.

This cooking blender has four heating methods: gas heating,electric induction heating, steam heating and thermal oil heating.

Gas heating cooking mixer: It can reach high temperature in a short time, and the strong flame can effectively cook the paste. In addition, an infrared flameless burner or a powerful blower can be optionally equipped to improve the heating efficiency.

Electric induction heating cooking mixer: It is a heating method that uses the principle of electromagnetic induction to convert electrical energy into heat energy. It has the characteristics of fast heating, precise temperature control, safety and energy saving. Electric induction heating has 8 gears of adjustment, which makes the operation safer and more convenient.

Steam heating cooking mixer:Coming from a steam boiler,steam goes into the jacketed space through the pipe and indirectly heats ingredients. This heating method is very energy efficient, so it’s ideal for mass production.This temperature control is optional.

Thermal oil heating cooking mixer: Use gas or electricity as the heat source to transfer heat to the thermal oil in the interlayer space to achieve indirect heating of the ingredients. It has a temperature control function and can cook the ingredients at a constant temperature.

2.Technical Data

| Heating method | Gas(NG/LPG/Alcoholic) | Electric induction | Steam | Thermal oil(Electric/Gas) |

| Pot capacity | 100L-600L | 100L-600L | 100L-600L | 100L-600L |

| Pot diameter | 700mm-1300mm | 700mm-1300mm | 700mm-1300mm | 700mm-1300mm |

| Stirring power | 1.5/2.2/3/3.7/5kw | 1.5/2.2/3/3.7/5kw | 1.5/2.2/3/3.7/5kw | 1.5/2.2/3/3.7/5kw |

| Control method | Button | PLC Touch Screen | Remote Control | AIO Control |

| Other functions | Automatic Weighing | Metering Pump | Water Pipe/Oil Filling Pipe | Temperature Control |

| Heating method | Gas(NG/LPG/Alcoholic) | Electric induction | Steam | Thermal oil(Electric/Gas) |

| Pot capacity | 300L-1000L | 300L-1000L | 300L-1000L | 300L-1000L |

| Pot diameter | 1000mm-1600mm | 1000mm-1600mm | 1000mm-1600mm | 1000mm-1600mm |

| Stirring power | 2.2/3/3.7/5kw | 2.2/3/3.7/5kw | 2.2/3/3.7/5kw | 2.2/3/3.7/5kw |

| Control method | Button | PLC Touch Screen | Remote Control | AIO Control |

| Other functions | Automatic Weighing | Metering Pump | Water Pipe/Oil Filling Pipe | Temperature Control |

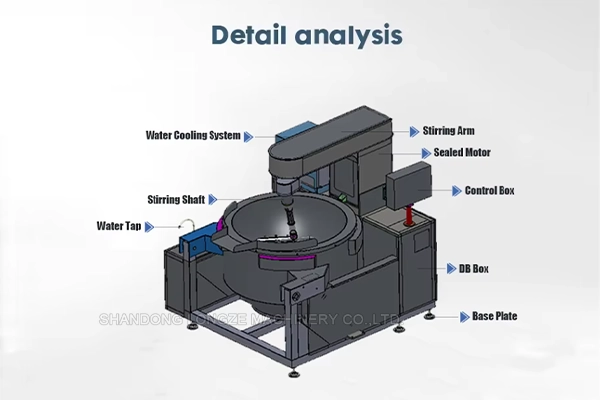

3.Structure and Features

4.Why Choose Our Industrial Cooking Mixer?

*The machine adopts a planetary stirring system, which can stir 360° without dead angles, and can thoroughly stir all the ingredients in the pot to ensure that nothing is missed.

*Equipped with PLC system for fully automatic operation.Programmable Workflows, Preset over 20 different curry sauce recipes (e.g., Thai, Indian, Japanese) allow one-touch operation, reducing manual intervention.

*The bottom of the pot is equipped with an automatic weighing system to ensure that the weight of each batch of materials is consistent and the product quality is guaranteed.

*Equipped with wireless temperature measurement and control system, real-time sensors adjust heating temperature (up to 280°C) and stirring speed (0-61r/min) to maintain optimal viscosity and prevent burning.

*Large capacity design enables efficient production. Each batch can produce 40kg/h-500kg/h, which can meet the production needs of different users.

5.FAQ

Q1: Why chooses LONGZE machinery?

A1:*We have more than 14 years experience in manufacturing food processing machines, more specialized in bulk production.

*More professional team in purchasing, producing, sales and technology, with excellent equipments.

*Have fast after-sales service.

Q2: How long is your delivery time?

A2: Generally, it will take 15 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3: How does your factory do in terms of quality control?

A3: Quality is priority.We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.