Vacuum Horizontal Mixer Machine

Discover industrial-grade vacuum horizontal mixer machine for jam, paste, preserves, sauces, pickles & more. Ensures 99% uniform mixing, protects nutrients. Get custom solutions!

content Us:+86 13402268227

1.Why Food Manufacturers Choose Vacuum Horizontal Agitator Mixers?

Whether you produce jam, paste, preserves, candied fruits, concentrated sauces, or seasoned pickles, achieving consistent texture, preserving natural flavors, and maintaining hygienic standards are critical challenges. Traditional mixers often cause oxidation, uneven blending, or cross-contamination risks.

2.Here’s how our vacuum horizontal mixer machine revolutionizes your production:

*Precision Mixing Under Vacuum

Eliminates air bubbles & oxidation → Preserves natural color & nutrients of fruits/vegetables

Ideal for jams, fruit preserves, tomato paste requiring vibrant appearance.

*Multi-Functional Agitation

Positive and negative bidirectional alternation mixing blades handle chunky, granular, pasty materials without damage

Adjustable RPM (0-80 rpm) for delicate fruits OR viscous sauces like mango pulp, chili paste

*Hygienic & Easy-Clean Design

Full stainless steel (304/316L) + CIP/SIP compatibility → Comply with food hygiene and safety standards

No dead corners → Reduces 80% cleaning time vs traditional mixers

*Energy & Cost Efficiency

Vacuum system reduces processing time by 30-40% → Lower utility costs

Dual-layer jacket supports heating, mixing and vacuum

3.Applications: Solve Your Specific Production Challenges

*Candied & Dried Fruits

Even sugar/seasoning coating on plums, apricots, pineapple slices without crushing

*Concentrated Products

Homogeneous blending of fruit purees, nut butters, baby food with zero lumps

*Pickles & Fermented Foods

Gentle mixing of kimchi, sauerkraut, spicy turnips while retaining crispiness

*Powder & Granule Mixtures

Dust-free operation for spice blends, instant soup bases, nutritional powders

4.Technical Highlights That Beat Competitors

| Feature | Specification | Benefit |

| Vacuum Level | Adjustable (-0.09)~(-0.05)MPa | Prevents oxidation & flavor loss |

| Mixing Capacity | 300L/500L/800L Customizable | Scale from pilot tests to full production |

| Temperature Control | 40℃-70℃ | Heating, Mixing and Vacuum |

| Motor power | 3-7.5kw | Different capacities require different motor specifications |

| Stirring Speed | 0-80r/min | The stirring speed can be adjusted according to the material properties and state |

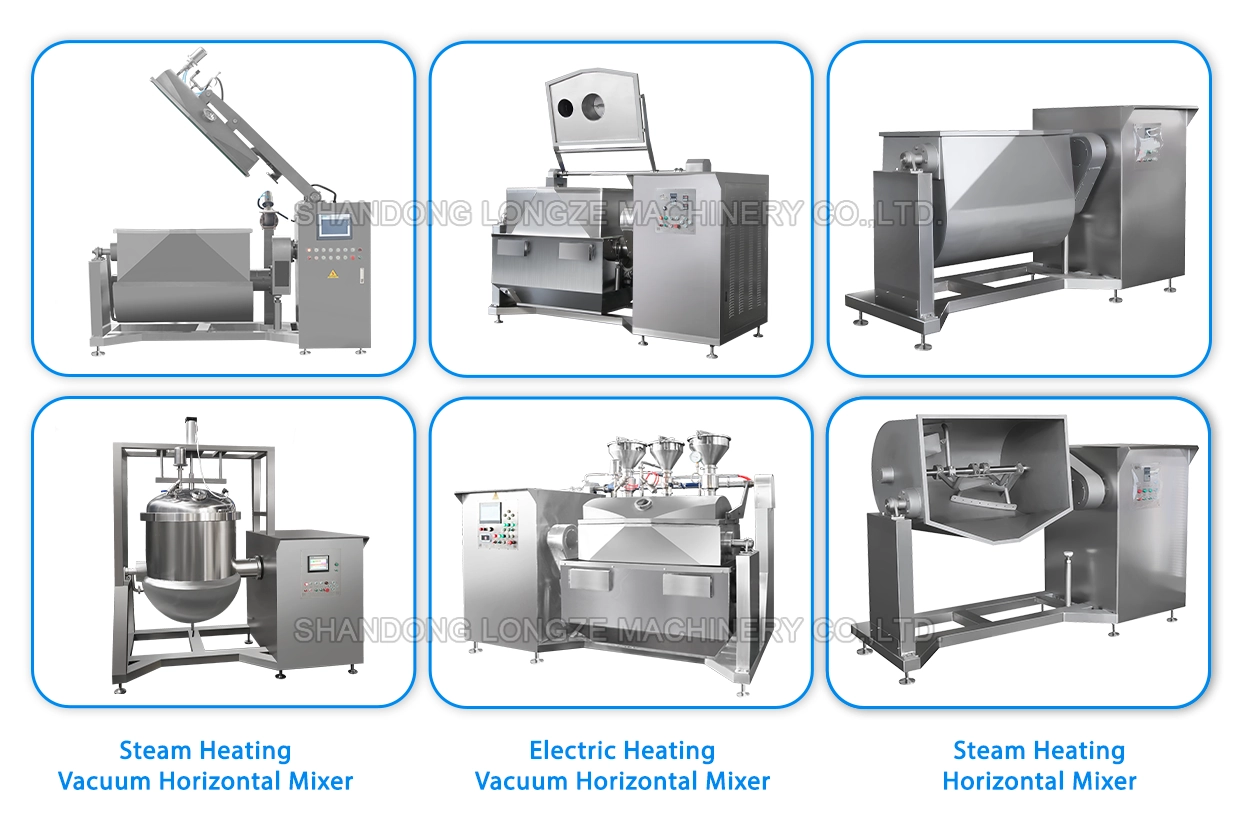

| Heating Type | Steam/Electric induction | There are two heating modes to choose from |

| Functions | Stirring/Heating/Vacuum | Can be customized according to material properties |

5.FAQs: Quick Answers for Buyers

Q1: Can it handle sticky materials like caramel or cheese?

A1: Yes! Our use high-quality stainless steel and Teflon scrapers. All accessories are manufactured by ourselves, with high machine compatibility and matching

Q2: How to validate mixer performance?

A2: Request FREE sample testing with your actual materials.

Q3: What’s the ROI period?

A3: Most clients recover costs within 14 months via reduced waste & energy.