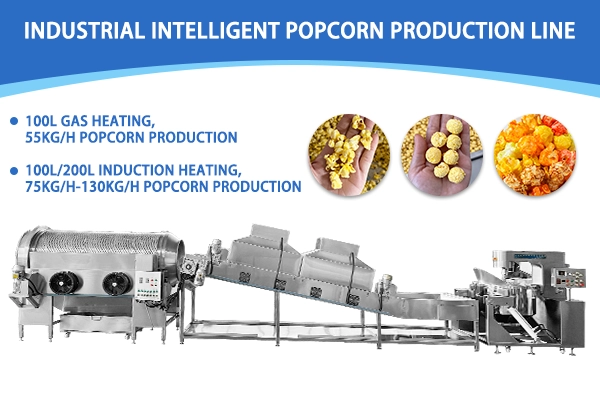

Selecting the right industrial popcorn machine impacts your production efficiency, operating costs, and product quality. As a leading manufacturer of heavy-duty popcorn processing equipment, we break down key factors to consider when investing in large-capacity systems (100L-200L) for commercial operations.

1.Heating Technology Showdown

*Gas Popcorn Machine (100L):

Ideal for locations with limited electrical infrastructure

Lower upfront cost | Output: 55kg/h

*Electric Popcorn Machine (100L/200L):

Precision temperature control for consistent popping

100L Output: 75kg/h | 200L Output: 130kg/h

30-36% higher efficiency than gas models

Reduced energy waste with electromagnetic heating

| Model | Heating Mode | Diameter | Motor Power | Stirring Speed | Discharge Type | Control Mode | Capacity | Overall Dimensions |

| Gas | LPG | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button | 55kg/h | 1207×1500×1500 |

| Electric Induction | Electric Induction 20kw | 700mm | 1.5kw | 0-80r/min | Automatically Hydraulic | Button/Intelligent | 75kg/h | 1565×1373×1606 |

| Intelligence Electric Induction | Electric Induction 40kw | 900mm | 2.2kw | 0-80r/min | Automatically Hydraulic | Button/Intelligent/Automatic Feeding | 130kg/h | 1541×1851×1675 |

Compare 100L gas vs 100L/200L electric popcorn machines. Discover which high-capacity industrial popcorn maker (55-130kg/h output) fits your production needs.

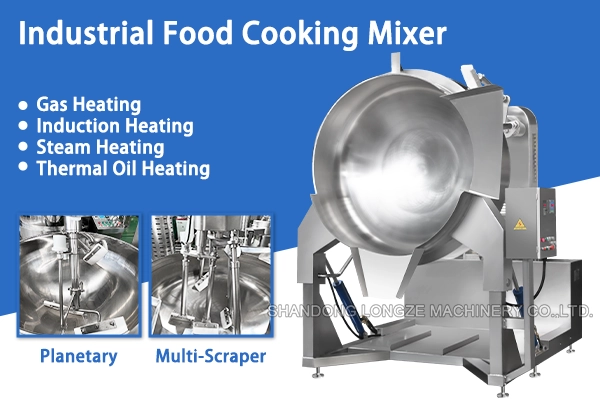

2.Why Oil-Popping Eliminates Coating Machine

Unlike hot-air poppers requiring separate flavor coating systems, our industrial machines deliver dual technological advantages:

①Direct oil-based infusion of caramel, cheese, or custom seasonings during popping – eliminating coating equipment

②Single-system production of both plump mushroom popcorn and light butterfly popcorn – zero hardware modifications needed

This cuts equipment costs by 32-40%, saves 15㎡ floor space, and enables instant flavor-shift flexibility for premium snack diversification.

3.Five Key Selection Criteria

*Throughput Requirements: Match kg/h to your daily demand

*Utility Access: Gas availability vs 3-phase electrical capacity

*Product Flexibility:

Must produce both mushroom & butterfly shapes

Ensure flavor infusion during popping (oil-based advantage)

*Footprint Constraints :

100L gas heating popcorn machine units require ≥3.13㎡ processing area

100L electric induction heating popcorn machine units require ≥3.48㎡ processing area

200L electric induction heating units require ≥7.62㎡ processing area

*Sanitation Design: Look for FDA-grade stainless steel construction

4.Conclusion

For small-to-mid operations prioritizing affordability: 100L Gas Machine delivers proven performance. For high-volume producers valuing efficiency: 200L Electric Popcorn Machine maximizes output with superior kg-per-kWh ratios. All models produce ready-to-pack flavored popcorn without secondary processing – a game-changer for industrial snack production.

Request a Free Production Analysis: Send us your daily output targets and facility specs for customized machine recommendations + throughput simulations.