The $2M Lesson: Why Your Sauce Mixer’s Heating System MattersPet Food Meat pastes, vitamin gels sanitation

When Gourmet Foods Inc lost a premium truffle sauce batch to scorching, they uncovered a brutal truth: 85% of product waste in viscous food production stems from mismatched heating systems. For sauces, pastes, jams, and growing sectors like plant-based spreads and pharmaceutical edibles, choosing wrong means:

— 37% material waste from uneven heat distribution

— 15% higher energy costs with inefficient heat transfer

— FDA non-compliance risks from temperature deviations

*Pro Tip: “Low-pH foods like tomato paste (pH<4.3) require ±1°C precision to prevent botulism – a non-negotiable in mixer selection.”*

Beyond Sauces & Jams: 4 High-Growth Applications

| Industry | Key Products | Critical Mixer Feature |

| Condiments | Ketchup, mayonnaise, mustard | Scrape-down blades |

| Nut Butters | Peanut/almond butter, tahini | Vacuum version available |

| Confectionery | Caramel, chocolate fudge | ±0.5°C temp control |

| Pet Food | Meat pastes, vitamin gels | sanitation |

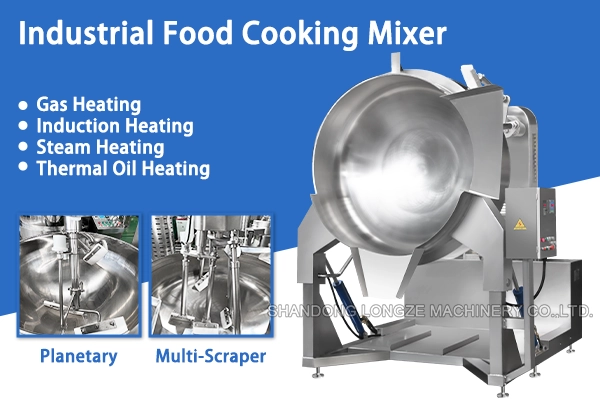

Heating Showdown: 4 Systems Compared (Data-Driven Analysis)

Which Heating Type Wins for Your Product?

| Feature | Gas | Electric Induction | Steam | Thermal Oil(electric & gas) |

| Best For | Fried food, sauces, fillings, etc.(Not suitable for materials with high starch content) | Fried food, sauces, jam,paste,fillings, syrup,etc.Tomato paste, nut butters,(Precise temperature control, suitable for most materials) | Fruit jams, dairy sauces(The heating is relatively gentle, suitable for high-viscosity materials and products with high starch content.) | sauces, jam,paste,fillings, etc.(The heating is relatively gentle, with strong timing and slow heat dissipation, which is suitable for high-viscosity materials and products with high starch content.) |

| Temp Precision | ±5°C | ±1°C | ±2°C | ±2°C |

| Max Temp | 260℃ | 260℃ | 110℃ | 260℃ |

| Energy Eff. | 98% | 96% | 80% | 88% |

| Scorching Risk | High | Low | None | None |

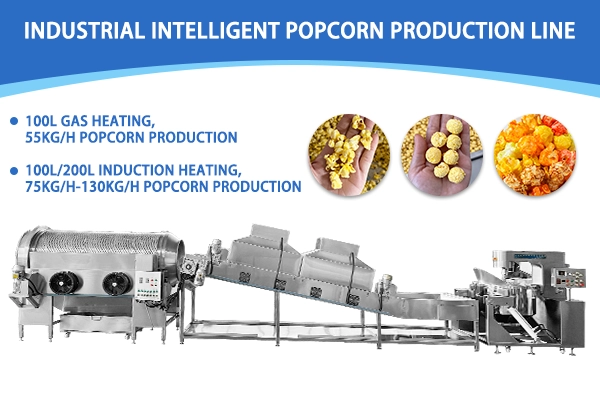

Capacity Calculator: Matching Size to Production Goals

100-300L: Ideal for R&D/small-batch producers (e.g., artisan preserves; output: 50-150kg/hour)

400L-600L: Sweet spot for mid-sized operations (e.g., nut butter line; handles 2 tons/hour)

700-1000L: Large-scale plants (e.g., industrial ketchup; capacity: 5+ tons/hour)

“Overfill by just 10%, and jam viscosity drops efficiency by 30% – always add 20% headspace!”

Your Action Plan: Next Steps

Step 1: Audit your product’s:

Viscosity range (cP)

pH level

Target batch size

Step 2: Match to heating type using our guide above

Step 3:Contact our staff to get a detailed introduction of the machine, determine the machine model, and get a quote for the machine.