If you work in food, pharmaceutical, or chemical processing, you’ve likely heard of jacketed kettles with agitators. But what exactly are they used for, and why are they indispensable in modern production lines? This guide breaks down their critical applications, heating methods, and industry-specific benefits.

Core Functions: Precision + Efficiency

Jacketed kettles with agitators combine uniform heating and controlled mixing in one vessel. The double-walled “jacket” circulates heating/cooling media (steam, thermal oil, etc.), while the internal agitator ensures consistent product texture. Key capabilities include:

Prevent scorching (critical for dairy/sauces)

Exact temperature control (±1°C with electromagnetic models)

Homogenize high-viscosity products (e.g., nut butters, thick pastes)

Reduce processing time by 30-50% vs. traditional methods

Top 7 Industry Applications

| Industry | Products | Advantages |

| Sauces & Condiments | Tomato sauce, mayonnaise, salad dressings | Prevents oil separation, ensures emulsion stability. |

| Dairy Processing | Cheese sauces, custards, puddings, yogurt bases | Gentle heating avoids protein denaturation; scrapers prevent milk solids buildup. |

| Confectionery Production | Caramels, fudge, chocolate, fruit fillings | Precise temp control for sugar crystallization; even mixing for smooth texture. |

| Ready-to-Eat Meals & Soups | Stews, broths, meal prep sauces | Scalable batch cooking (100L R&D → 600L full production). |

| Pet Food Manufacturing | Wet food gravies, meat blends | Handles high-fat content |

| Pharmaceuticals/Cosmetics | Ointments, creams, gel bases | GMP-compliant SS 316L construction |

| Chemical & Specialty Processing | Adhesives, lubricants, industrial compounds | Corrosion-resistant materials; thermal oil heating for high-temp reactions. |

Why Choose a Jacketed Kettle with Agitator?

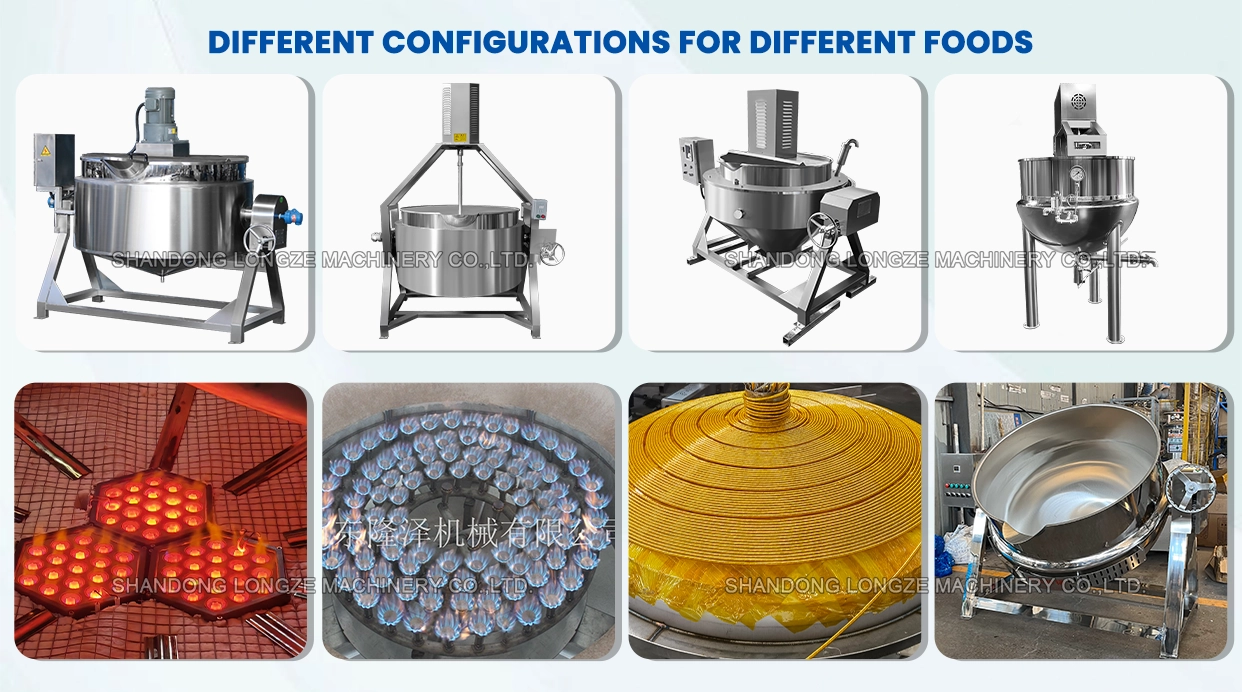

1.Versatile Heating Methods (Choose Your Optimal Solution)

Gas Heating: Fast heat-up times, ideal for facilities with existing gas lines. Cost-effective operational fuel.

Electromagnetic Heating: Ultra-precise temperature control, incredible energy efficiency, clean operation, perfect for sensitive products. A modern, high-performance choice.

Steam Heating: Gentle, uniform heat transfer. Excellent choice if your facility has a reliable steam supply (boiler).

Thermal Oil Heating: Enables high-temperature processing (above standard steam temps) safely and consistently. Essential for applications like high-temperature frying or confectionery.

| Heating Type | Best For | Key Advantage |

| Gas Heating | High-throughput sauces/soups | Fast heat-up; low operational cost |

| Electromagnetic Heating | Temperature-sensitive dairy/confections | Energy-efficient; ±1°C precision |

| Steam Heating | Pharmaceuticals/cosmetic emulsions/Sauces/jam/high viscosity fillings | Gentle, uniform heat transfer |

| Thermal Oil Heating | Sauces/jam/high viscosity fillings | Handles 260°C+ safely |

2.Precision Agitation: Our agitators are engineered for performance:

Variable speed control for optimal mixing at different process stages.

Robust gearboxes and seals for reliability.

Multiple agitator styles (paddle, anchor, helical ribbon) available to match your product viscosity and mixing requirements.

Scrapers (optional) prevent buildup and ensure efficient heat transfer.

3.Heavy-Duty Construction:

Food-Grade Stainless Steel (304/316L) contact surfaces.

Reinforced jacketing and structural supports.

4.Industrial-grade motors and components.

Smart Customization: This is where the real value shines:

Specific Capacity: Need a 350L kettle? We build it.

Port Configuration: Position and type (TC clamp, flanged, sanitary) of inlet/outlet ports tailored to your line.

Agitator Design: Select the perfect type and speed for your product viscosity (thin sauces vs. thick pastes).

Control Systems: From basic manual to advanced PLC-based automation with recipe management.

Tilting Mechanism: Manual or hydraulic tilting for easy discharge.